Weighing a Production Platform: Any Load, Any Challenge

Categories

by: Alan Haig-Brown

The challenge: To Prepare a Gas Production Platform for Transport by Ship Across Ocean

The platform would be loaded on to a heavy lift ship at a seaport using dollies with dozens of rubber tires to move it. The rubber-tired dollies will need to distribute the weight over their total number. The heavy lift ship will have to add ballast to get the wide, open, after-deck down to the level of the load-out dock. Then, as the dollies roll the massive weight of the platform aboard, ballast water will have to be pumped, out of the ship, in an amount that equals the weight of that part of the platform that is already aboard. This is a delicate operation designed by specialized engineers who calculate the weight on the dollies, the weight of the volume of ballast water and the timing of the pumping that will maintain a level load-out between the pier and the ship.

It is well known that a cubic meter of water weighs 1000 kg (2200 pounds). Saltwater, with slightly varying densities, weighs about 1026 kg (2260 pounds) per cubic meter. So for the engineers to calculate the amount of ballast water that would have to be pumped from the ship, as the heavy platform and it’s many-wheeled dollies rolled on, could be calculated.

The platform was actually built in two sections that would eventually be placed onto the legs on land. This is the kind of thing that engineers love and it is a fairly straightforward task. They need only get the weight of the platform and then calculate the amount of water to be removed from the ship as it rolls onboard.

But it is more complex than that. The platform had been built from plans that gave it about two dozen short legs that were designed to mate with a prepared site thousands of kilometers away in a different country. Rubber-tired dollies would support each of these stubby platform legs, but they did not have the platform’s weight equally distributed to each one of them.

It was not a matter of simply weighing the whole structure and dividing by the number of legs. The bearing weight near each leg would have to be known to the engineers and this weight could only be accurately measured if each leg-area was lifted and weighted at the same time.

A method had to be devised to lift the total platform as though on its legs all at the same time and get a weight of the pressure near each leg. At that point the people at Anyload were brought into the project. As their name suggests they are committed to building highly accurate load cells capable of weighing any load, from a few milligrams up to thousands of tons.

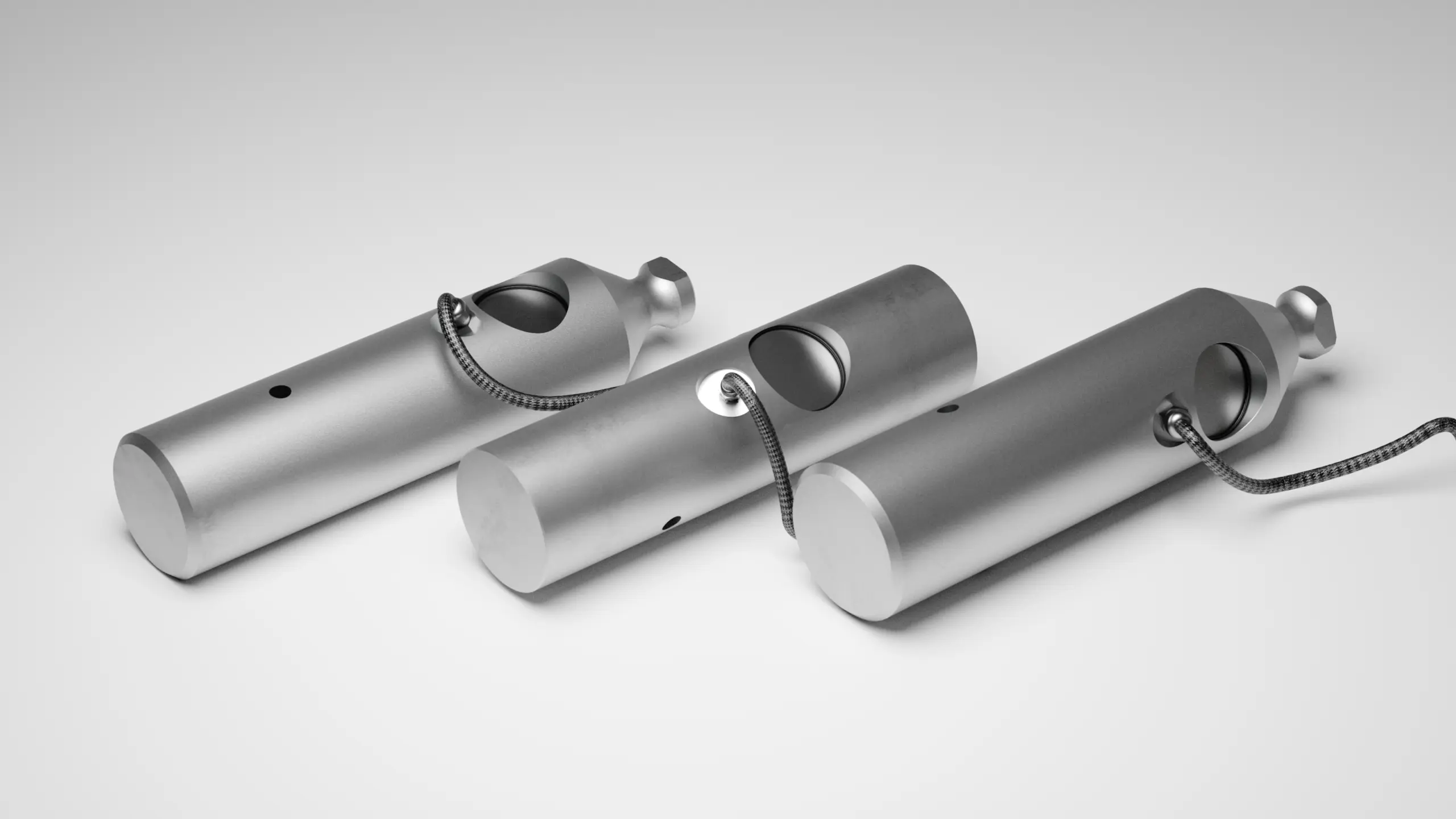

The designers in the research department at Anyload, took on the challenge. They developed a unique load cell specifically for this job. Anyload designed and built a series of circular disk load cells that could be placed between the hydraulic lifting jacks and the structural beams adjacent to the legs.

Each of the 25 disc load cells, supplied by Anyload, had a diameter of 346 mm, a depth of 180 mm and weighted 90 kg. Simple handles were affixed to each side for ease of manual lifting. Also on each disk load cell, there are two connectors, one each side of a junction box on the load cell body, each connector has one independent strain gage bridge. These strain gauges have been calibrated with the indicator individually, so in case of one load cell bridge failing on site, the second strain gage bridge will still provide the data.

With the weight on each of the legs determined it was seen that the platform had a total weight of 1900 tons. Engineers responsible for the load-out to the heavy lift ship were able to determine the arrangement of the dollies and, most importantly, a schedule for the de-ballasting of the heavy lifts ship. The all-important information would also be used again at the other end of the voyage for the off load of the platform and when the individual legs would mate with the prepared site.

It was a challenge to design the right load cell for this complex task. But it is the kind of challenge that is welcomed by the engineers at Anyload. Having been successfully completed, it is one more project in Anyload’s growing list of quality load cells for any application from milligrams to tons.