Categories

There is a saying that “innovation is one part idea and nine parts hard work”. In engineering that can be expressed as “one part need and nine parts hard work”. It was a clearly expressed need that led the ANYLOAD to recently develop an innovative shear beam foot 500kg load cell. Larger load cells of this type are relatively easy to produce as the weight that causes elastic deformation of the load cell can be designed to any size and length so long as the engineering is precise.

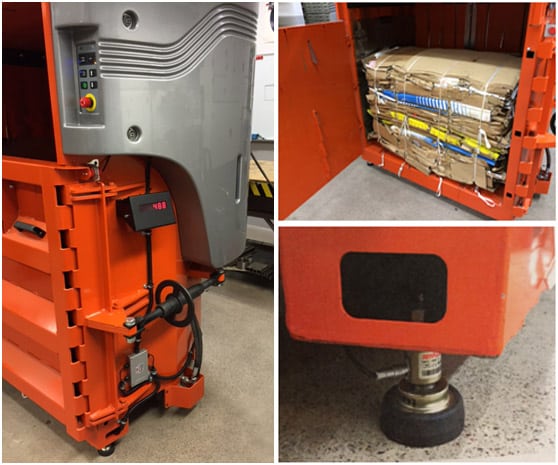

In the summer of 2014, CEO Gary Y Gui of ANYLOAD visited their loyal key distributor Patrik Viktorsson from Vetek – a leading load cell, scale, and weighing components distributer in Scandinavia. During the meeting, Viktorsson asked Gui if ANYLOAD could provide a solution for one of his customers. The customer had a heavily built bundling and strapping machine for cardboard waste. He had to accurately weigh the cardboard while in the machine to produce uniform sized bundles. There was very little space available and the load cell needed to be easy to install. After brainstorming for some time, Viktorsson suggested a design that miniaturized the load cell element onto a normal shear beam swivel foot. Such a design could not require any complicated and bulky weigh modules and installation would be as simple as screwing the compact swivel foot – turned load cell foot – into the supports of a platform.

So with the first of ten parts decided, GUI assured Viktorsson that his team could find an innovative solution to the challenge. On his return to the ANYLOAD company, GUI met with his team. GUI assured Viktorsson that a solution would be found with the tools and technology ANYLOAD had developed and perfected over years. One of these technologies is the Spring Web design, perfected with the finite element analysis tool – a computerized method for predicting how a product reacts to stress, and other physical effects.

The Spring Web design, developed by ANYLOAD years earlier, provided the optimum foundation for strain gauge bonding. The traditional design of canister load cell on the market uses the single column design, which needed the semi-conductor gauges to compensate the non-linearity for such a design. However the semi-conductor gauges are very fragile and sensitive to the temperature shifts compared with the normal load cell strain gauges. The modern digital canister load cell can use the software to compensate the non-linearity without the help of semi-conduct gauges, but more than 10 times of electronic components were brought into the load cell, increased much failure rate of digital truck scale load cell. The Spring Web design provided a nature perfect linearity, without the help of semi-conduct gauges, this is one of the key reason ANYLOAD canister load cells have a much lower failure rate when being used for truck scale. The Spring Web design was essentially two sink holes –round or oval shape – on opposite sides of the load cell column that created two flat areas. These flat areas made excellent surfaces for strain gauge bonding and most importantly, dramatically reduced vibrational stress by uniformly distributing stress. Therefore, the strain gauges can withstand the substantially larger amounts of vibrational stress commonly found in truck scales. Such technology can be found in all of ANYLOAD’s canister load cells, and ANYLOAD’s unique compact tension link load cell; all of which had achieved varying classes of NTEP (up to class III single cell 6,000D & Class IIIL 10,000D) and OIML approval (up to C6).

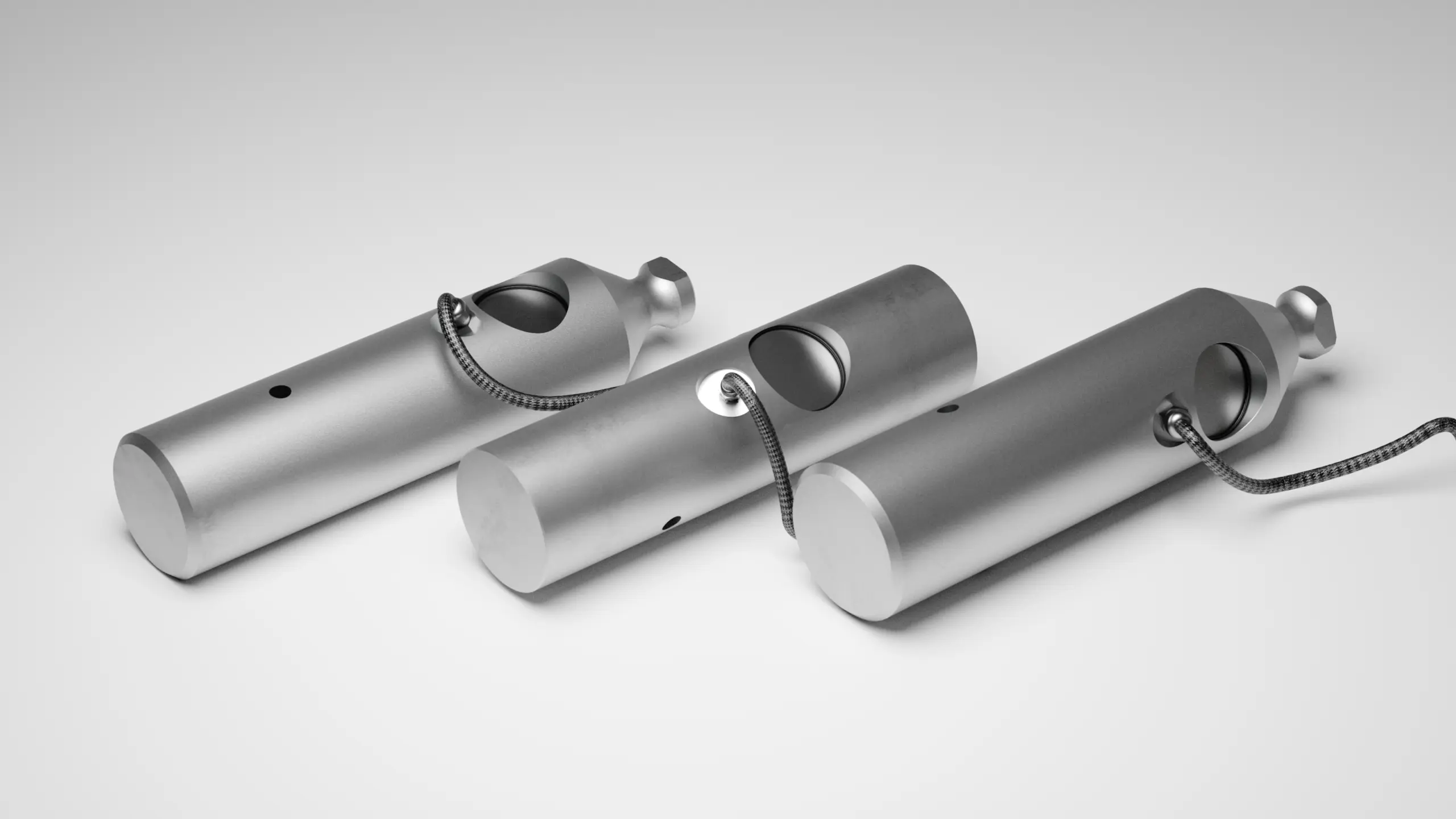

Though the Spring Web design provided the foundation for strain gauges, intensive testing needed to be conducted to ensure such a miniaturized design could be accurately viable for the scale industry. The finite element analysis tool helped the engineering team pinpoint exactly how the newly developed instrument would react to real-world forces need for real samples. Following several prototypes and tests, the ANYLOAD engineering team was able to get the samples to achieve 0.03% total error or less; launched to the global market, the aptly named, FatFoot, qualifies for OIML C3 and NTEP Class III single 3,000D or Multiple 5,000D approval.

The FatFoot was designed, tested and ready to work only six months after the meeting between GUI and Viktorsson. Initially some customers expressed concern, “Could such a compact design be as strong as a shear beam load cell?”

GUI’s answer was unequivocal; “It’s stronger than a shear beam load cell with a swivel foot,” He explained, “The shear beam load cell with a swivel foot would cause enormous bending movements on the load cell and the base, but there are no bending movements in the FatFoot and the installation base of the FatFoot. The Spring Web in the FatFoot is stronger than the threaded stud; in fact the threaded stud will break before the Spring Web.”

Other customers, with harsh environmental applications, worried about damage or inaccurate readings resulting from water and particles of dust or sand that might get into the bearing gap. ANYLOAD’s Australian distributor suggested a solution. David Duncan from the company Associated Scale Service recommended designing a rubber boot that would cover the bearing area and prevent damage to the ball bearing. Three months later, a high quality rubber boot was offered as an option. The rubber boot encloses the entire bearing area and thus, protects the ball bearing and prevents any foreign particles from affecting the long term accuracy.

When Viktorsson received the FatFoot, he was delighted with the possibilities he could envision with the FatFoot. With a thread-in for installation and thread-out for replacement or maintainance, a professional technician was not required for installation. Viktorsson’s clients immediately installed the FatFoot into a powered live-stock feed-baler; the farmer could now apply the proper rate of preservative and measure forage yields without the need for a complex weighing system.

Other uses for the FatFoot are with hospital medical beds, veterinary benches, hopper scales, tank weighing, and much more. Basically any platform with supports that needs a compact and simple solution can be made into a weighing device! The capacities of Fatfoot ANYLOAD are making now is from 1Klb/500kg to 20Klb/10t, “But it’s unlimited which can be as low as 100lb/50kg and as high as 200Klb/100t” , said GUI.