Load Cell Selection Guide

Last Updated On May 28 • 12 min read

How Do I Decide Which Load Cell I Need?

There are many standard and custom load cell options available, with many different approaches possible for each weighing application. However, understanding the types of load cells that are commonly available and the various factors that are typically accounted for will help ensure that the right product is selected for the application.

The following guide is intended to provide a general orientation to the basics of load cell selection. Exceptions frequently apply, so we recommend contacting us and our team of experts who can provide the best solution for your application.

1. What is the Load Cell Application?

- Retail — Frequently requires legal-for-trade approved products.

- Food Processing — Washdown environments are frequent.

- Oil & Gas — Intrinsic safety and non-incendive requirements may apply.

- Automotive & Mobile Weighing — High safety factors and digitized output such as CANBUS are required.

- Agricultural — Harsh environments including corrosion protection against salt and fertilizers.

- Process Weighing — Fast response time load cells are often favoured relative to absolute precision.

2. What Type of Load is Being Applied

The type of force that is being applied is a major factor in considerations for which load cell to use. Consider the following factors when selecting:

Capacity of the Load

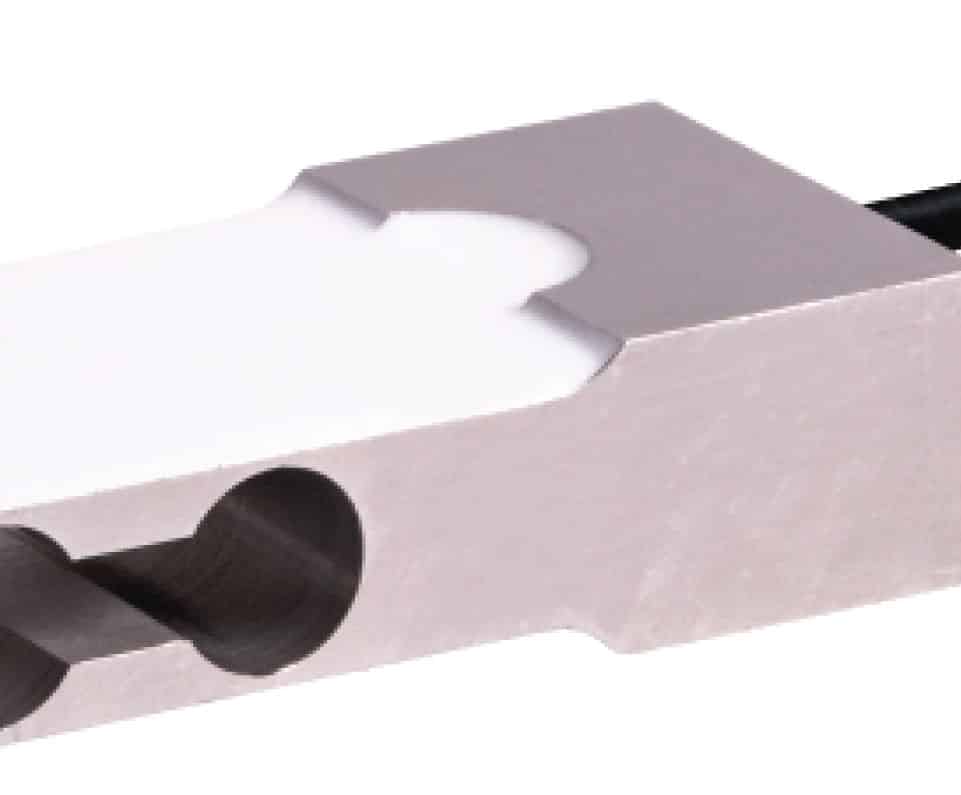

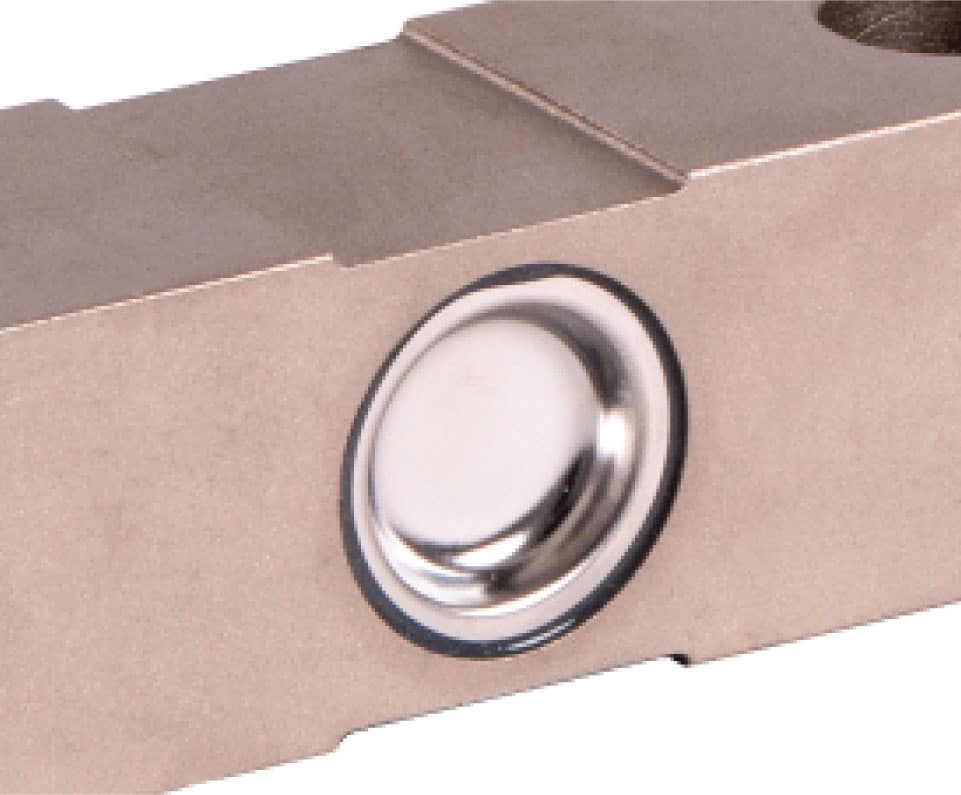

Different types of load cell are well-optimized to measure different loads. Besides other characteristics, certain load cells may excel in weighing lighter loads while being unsuitable to measure heavy loads due to their structural design. A cantilevered beam design, for example, is only efficient in applications under ~10t after which it is recommended to use a double-ended beam or canister load cell. As load cells are intended to be load-bearing, mechanical safety is also an important consideration.

Direction of Applied Load

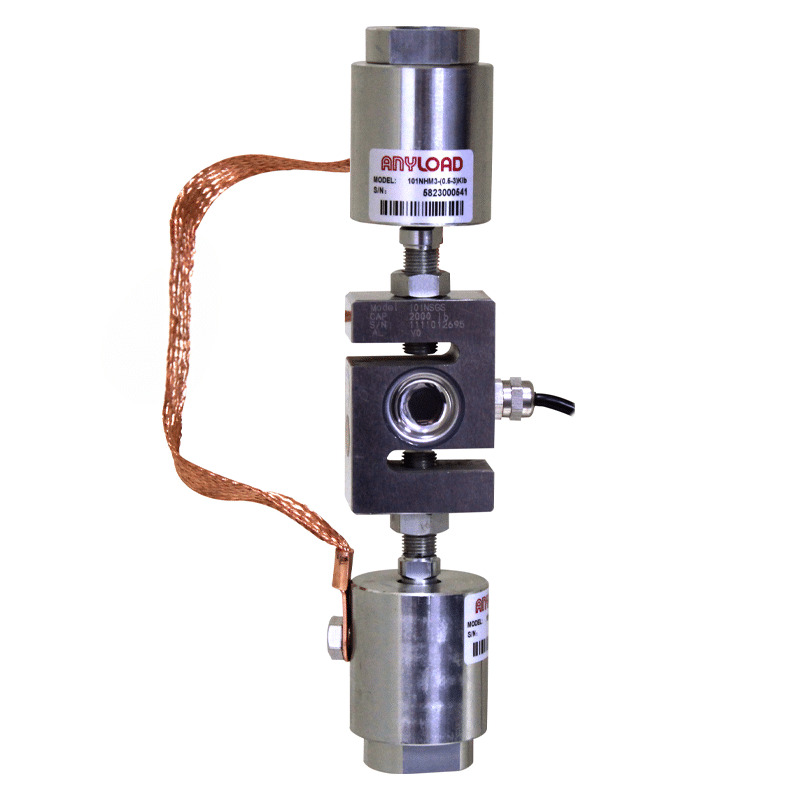

Loads can be applied differently depending on the nature of the application, the use of weigh modules, and the design of the load cell. Some applications may call for a load to be applied in tension to a load cell installed above a structure being weighed whereas others may require a compression weighing solution with load cells installed underneath a loading platform. Torque and multi-axial solutions may also be necessary for more complex situations.

Static vs. In-Motion Weighing

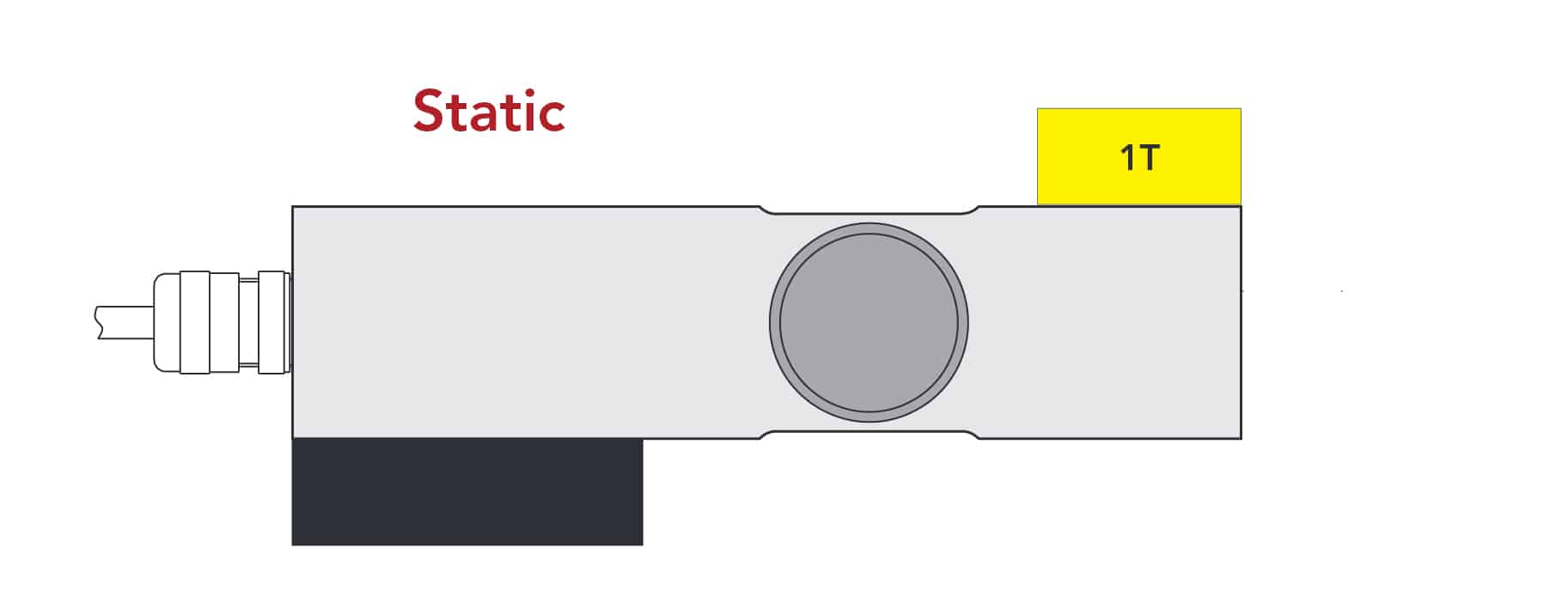

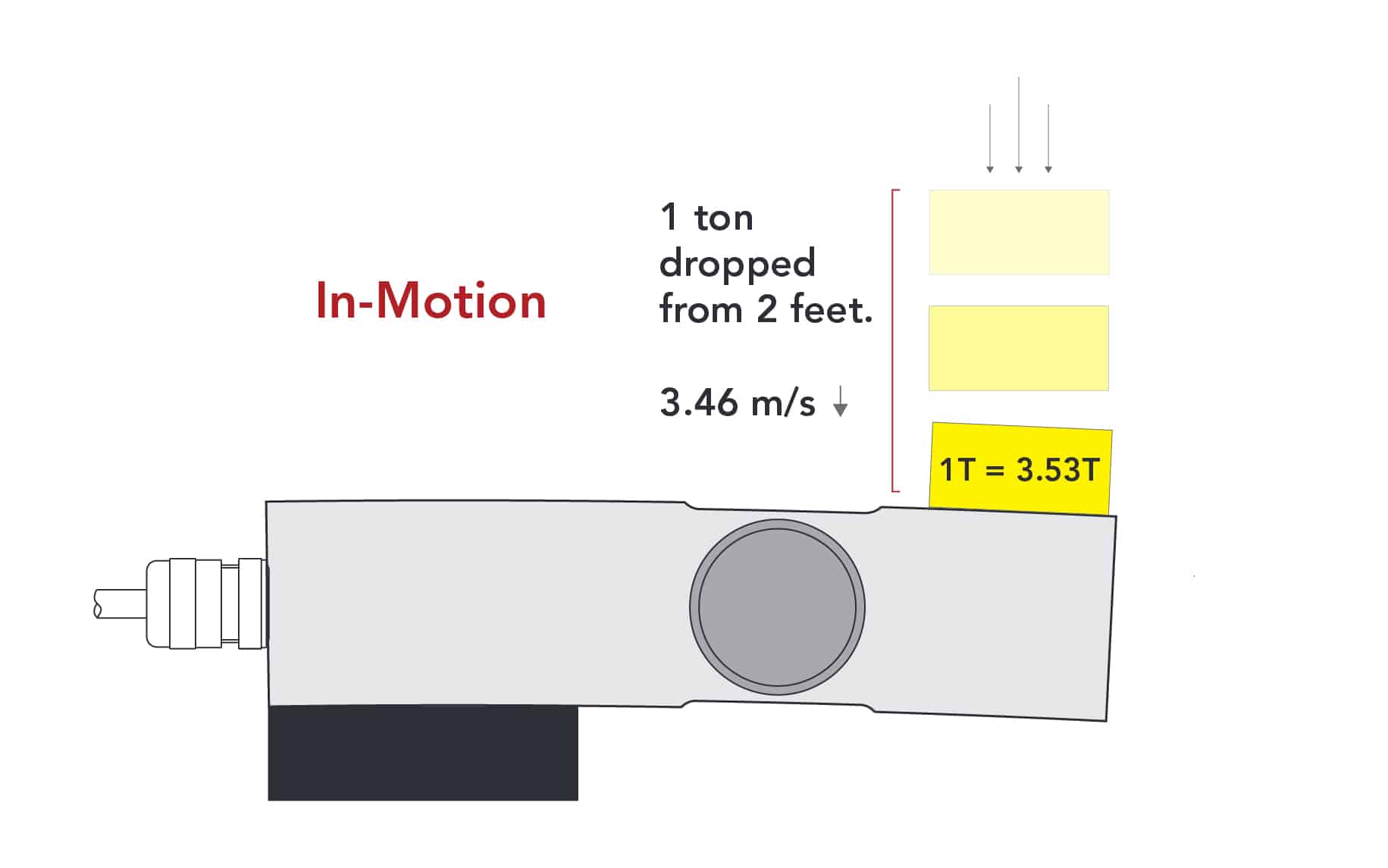

Static weighing refers to when a load is only applied without significant movement or acceleration, where a load is generally being applied relatively gently to a weighing system. There is some over-capacity safety that is recommended for most applications where precision is not paramount. Weighing in-motion typically involves significant risk for shock loading and overloading, which requires a load cell to be significantly higher capacity than the load it is intended to weigh.

Load Capacity:

Single Point (~100g to 1000kg)

Planar (~3g to 500kg)

S-Beam (~100g to 10t)

Load Button (~1kg to 10t)

Single Ended Beam (~5kg to 10t)

Tension Link (~1t to > 100t)

Load Pin (~2t to >100t)

Double Ended Beam (~2t to >200t)

Canister (~5t to >200t)

Note: Capacity ranges above are generalizations for standard products.

3. What are the Performance Targets?

Accuracy is a general description typically measured in divisions but involve multiple definitions relevant in certain high-performance applications and to industry professionals (creep, hysteresis, zero balance, etc.). Some questions that may be helpful in this process is to define answers to the following:

What is the minimum resolution that can be accepted for the application?

Load cells have performance ratings based on projected and tested resolutions. This can be expressed in percentages or more commonly in the weighing industry, divisions (d). For example, a resolution of 0.1kg for a 500kg capacity scale can be expressed as 0.02% or 5000 divisions.

What is the required safety factor?

There is typically an inverse relationship between capacity and resolution. Certain applications are more prone to overloading, shock loading, or require uplift protection. There are load cells that offer higher safety factors while others are designed for sensitivity. It is imperative to take this into consideration when selecting the load cell type, model, and capacity.

4. What is the Application Environment?

A load cell is a sensitive piece of technology that is designed to provide precise measurements. Environmental conditions must be considered to ensure that a load cell can perform reliably. Corrosion and moisture are two of the most common causes for load cell failure, and is thus the starting point when selecting a load cell as the material and the sealing of the load cell can have a significant impact on its survivability under harsh conditions.

Materials:

The type of material that a load cell is made of generally determines its resistance to corrosion. Certain materials may also perform better against specific corrosive chemicals.

- Aluminium — Aerospace grade aluminum with zinc electroplating provides some degree of salt corrosion resistance

- Alloy Steel — Durable alloy steel with nickel plating provides some degree of corrosion resistance

- Stainless Steel — Highly durable and offers the best corrosion protection

- Titanium — Exceptional durability and corrosion resistance but at very high cost

The type of sealing that encapsulates the electronic components of a load cell has a direct impact on the its durability against environmental conditions. In harsh environments, welded and hermetic sealing is advised whereas glue sealing can be sufficient in other applications. Weld sealing can sometimes have minor effects on accuracy relevant at lower capacities.

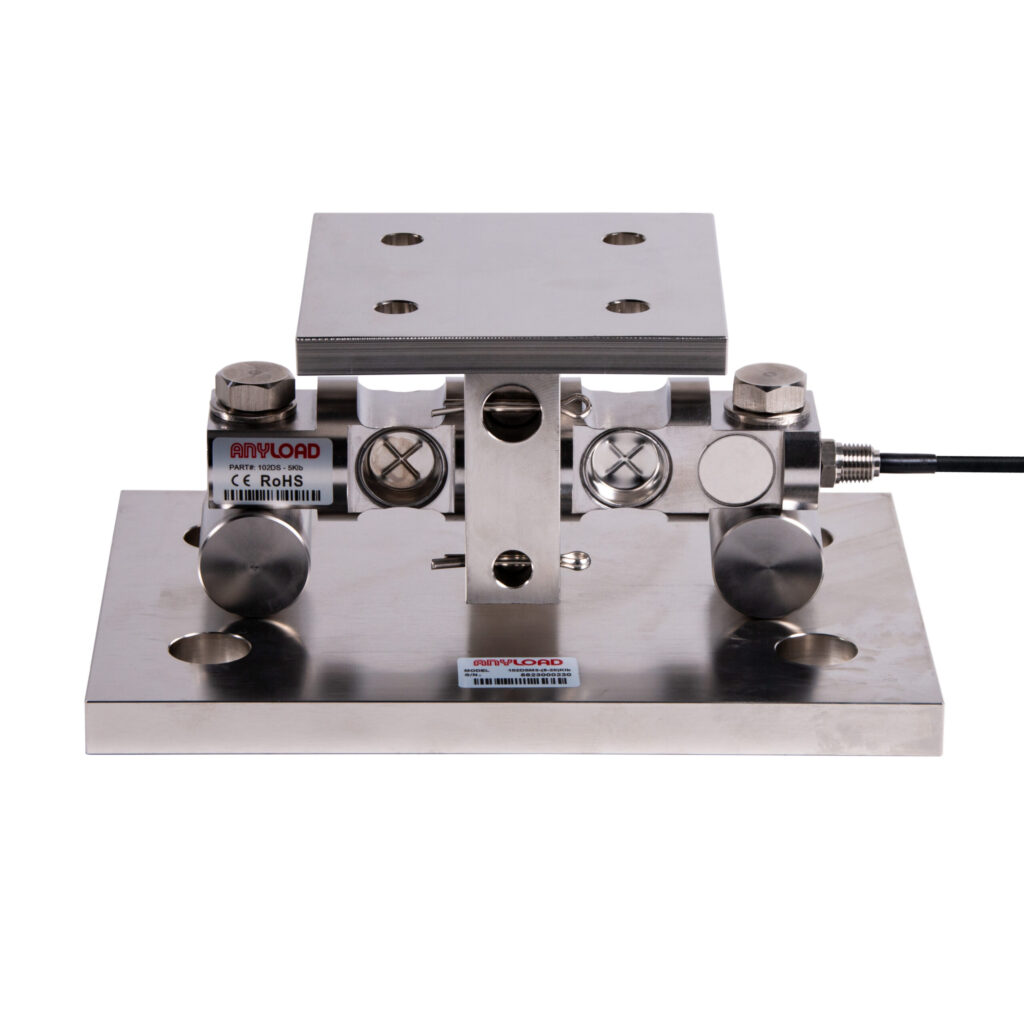

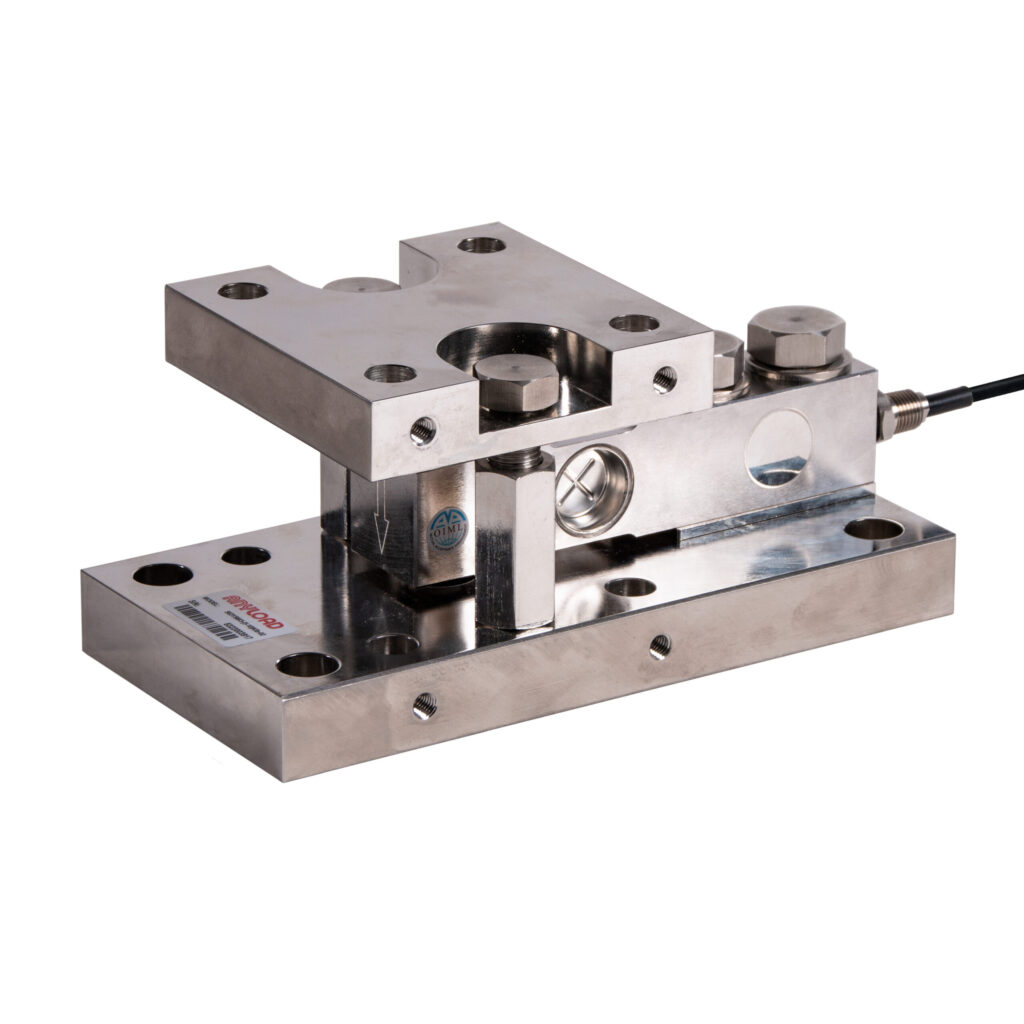

Weigh Modules:

Specialized mounting hardware designed to transform standard industrial structures like tanks, hoppers, conveyors, and platforms, into precise weighing systems. Weigh modules isolate the load cell from unwanted forces, ensuring the longevity and performance of a weighing system.

Additional Environmental Factors:

- Extreme temperatures (less than -50°C / -58°F or more than 65°C / 149°F)

- Use of abrasive or high pressure cleaning

- Vacuum or pressurized atmospheres

- Underwater operations (full submersion >3m depth)

Load cells expected to operate under these additional factors typically require a custom solution.

5. Are Approvals Needed for the Weighing Application?

Legal for Trade Approvals:

Any commercial applications where product is sold by weight generally requires that the weighing equipment is ‘legal for trade’ approved. In most jurisdictions, this typically means that the load cells used must be certified by a national and/or international body. An applicable legal for trade requirement helps to narrow down the viable options available for consideration.

- NTEP (US-specific) — Requires that all load cells used in commercial weighing applications to be NTEP certified.

- OIML (International) — Common global standard that load cells may be certified legal for trade and recognized in over 50 countries around the world, including most of Europe, Asia, and South America.

- Measurement Canada (Canada) — Legal for trade measurement systems must be certified by an accredited inspector and use either NTEP or OIML-certified load cells.

- National Measurement Institute (Australia) — Legal for trade measurement systems must use load cells certified by the Australian government after OIML certification is obtained.

Intrinsic Safety Certifications:

In environments with explosive atmospheres, it’s critical that all electrical equipment, including weighing systems and load cells, adheres to stringent safety standards. These certifications ensure that the equipment is designed and manufactured to avoid risk of any possible ignition sources in hazardous environments.

- ATEX (Europe) — A mandatory certification for equipment intended for use in explosive atmospheres within the European Union. ATEX-certified load cells are rigorously tested to ensure they do not initiate an explosion due to electrical sparks or high temperatures.

- IECEx (International) – An international certification that facilitates the global trade of equipment used in explosive environments. IECEx-certified load cells meet the highest international safety standards, ensuring their safe operation in hazardous conditions worldwide.

- FM (US) (North America) — Factory Mutual Global certification, recognized in the US and Canada (cUS marked), ensures that load cells are safe for use in specified hazardous environments. This certification confirms that the equipment has been tested for safety and performance according to North American standards.

6. Consult with Experts

ANYLOAD is in the problem solving business.

Our experienced team and global network of service providers can help take the stress out of the selection process by consulting with you directly. By understanding your specific needs, we can handle the intricate technical considerations, ensuring you get the most suitable and efficient load cell for your application.

Submit an inquiry and let us take the weight off your shoulders.