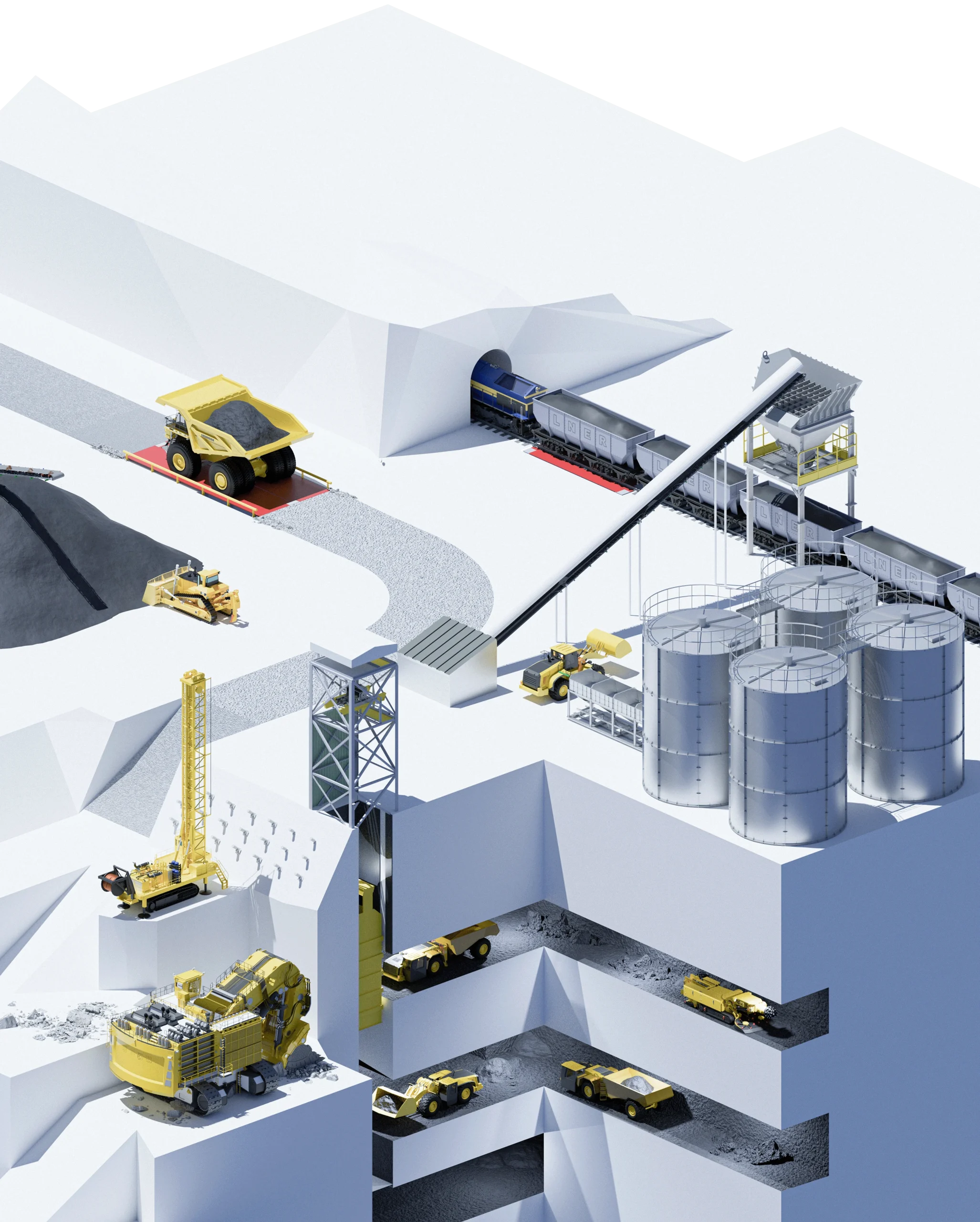

Mining

Weighing and Force Measurement for Extreme Environments

ANYLOAD provides high-precision load cells, force sensors, and weighing systems designed to meet the demanding requirements of the mining industry. Whether you are an OEM manufacturing heavy machinery, a mining company optimizing site operations, or a dealer servicing mining equipment, our solutions are trusted for their accuracy, durability, and customizability in the harshest environments.

Trusted Across the Mining Industry

- OEM Equipment Integration: Customizable load cells and sensors integrated into mining machines like crushers, haul trucks, conveyors, and drilling rigs.

- Site Operations: Reliable weighing solutions for tank scales, hopper systems, conveyor belt monitoring, and portable axle scales to streamline processes and ensure compliance.

- Dealer Support: A comprehensive product portfolio to meet the servicing and replacement needs of mining equipment.

Why ANYLOAD for Mining?

- Rugged and Reliable Designs: Engineered to perform under extreme conditions, including heavy loads, impact forces, and hazardous environments.

- Custom Solutions: Tailored designs, in-house testing facilities, and compatibility with outputs like CAN bus, RS485, and RS232 for seamless integration into mining machinery.

- Global Expertise: With decades of experience, our products are utilized in mining projects worldwide, earning a reputation for precision and reliability.

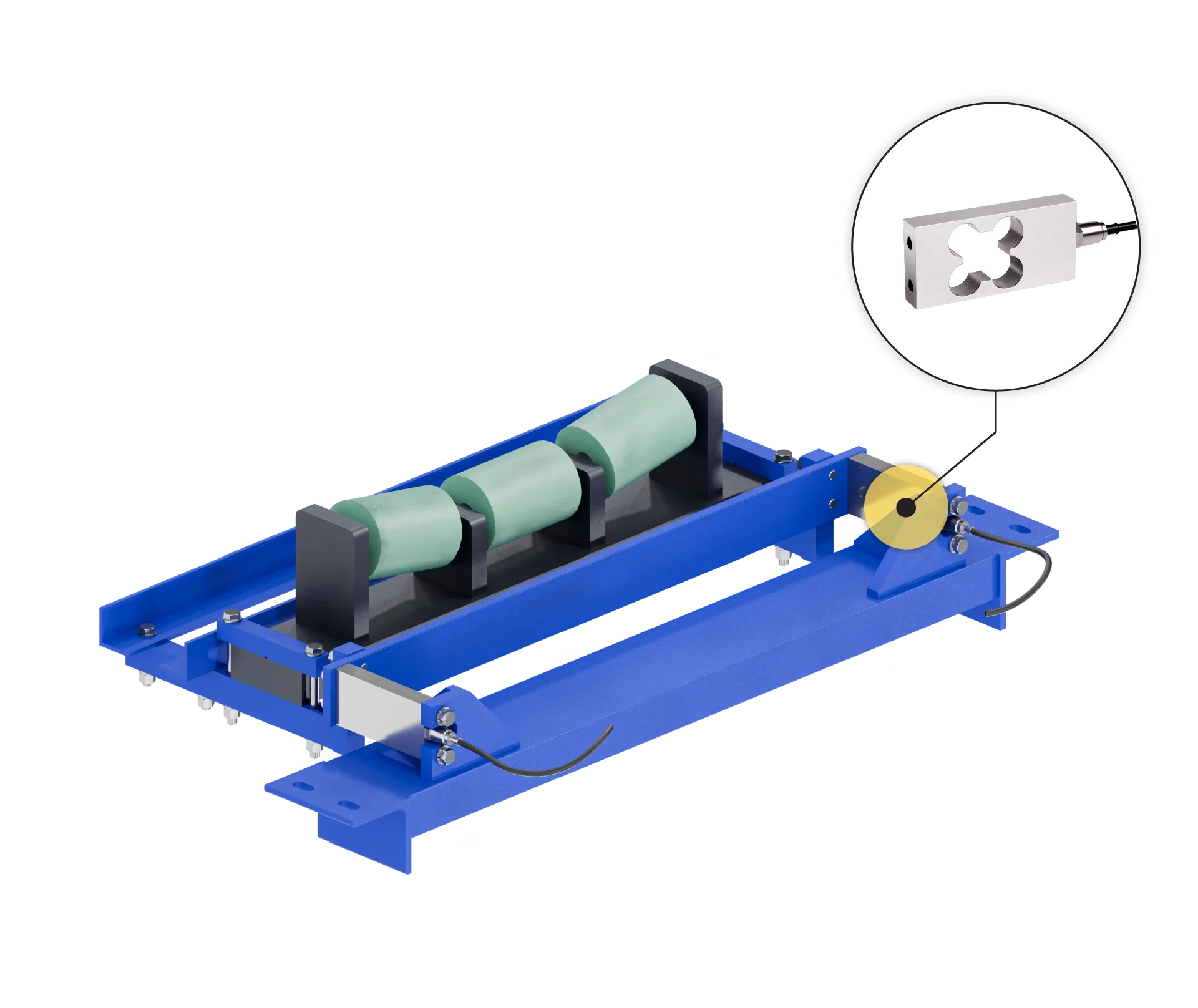

Belt Scales

Conveyor systems are the backbone of mining operations, transporting materials such as ore, coal, and aggregates efficiently across sites. Reliable weight measurement on conveyor systems is critical for process control, inventory tracking, and optimizing material flow in production and logistics management. It ensures efficient blending operations, precise feeding equipment control, and compliance with transport weight limits while minimizing waste and preventing equipment overloads.

View Products:

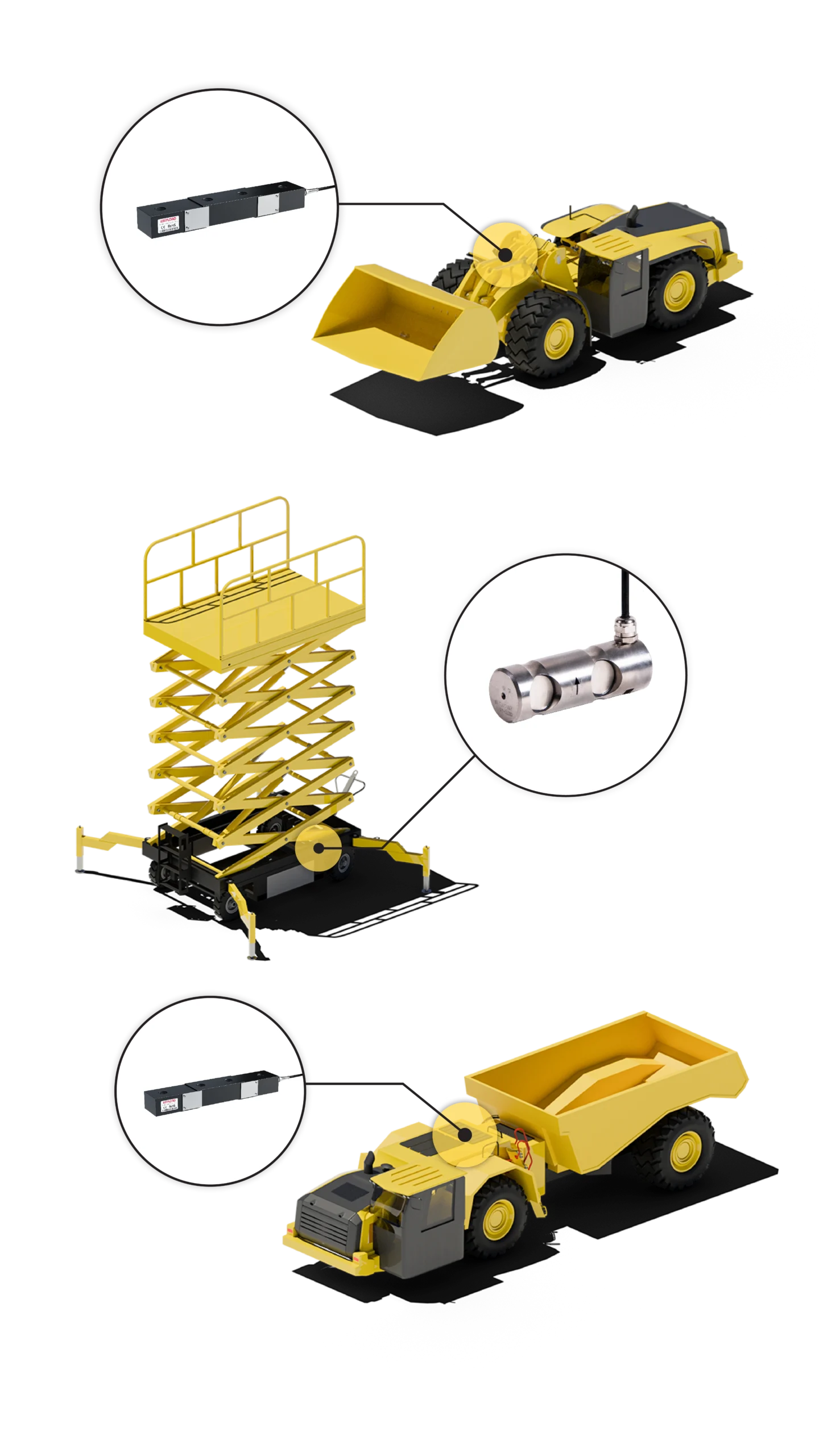

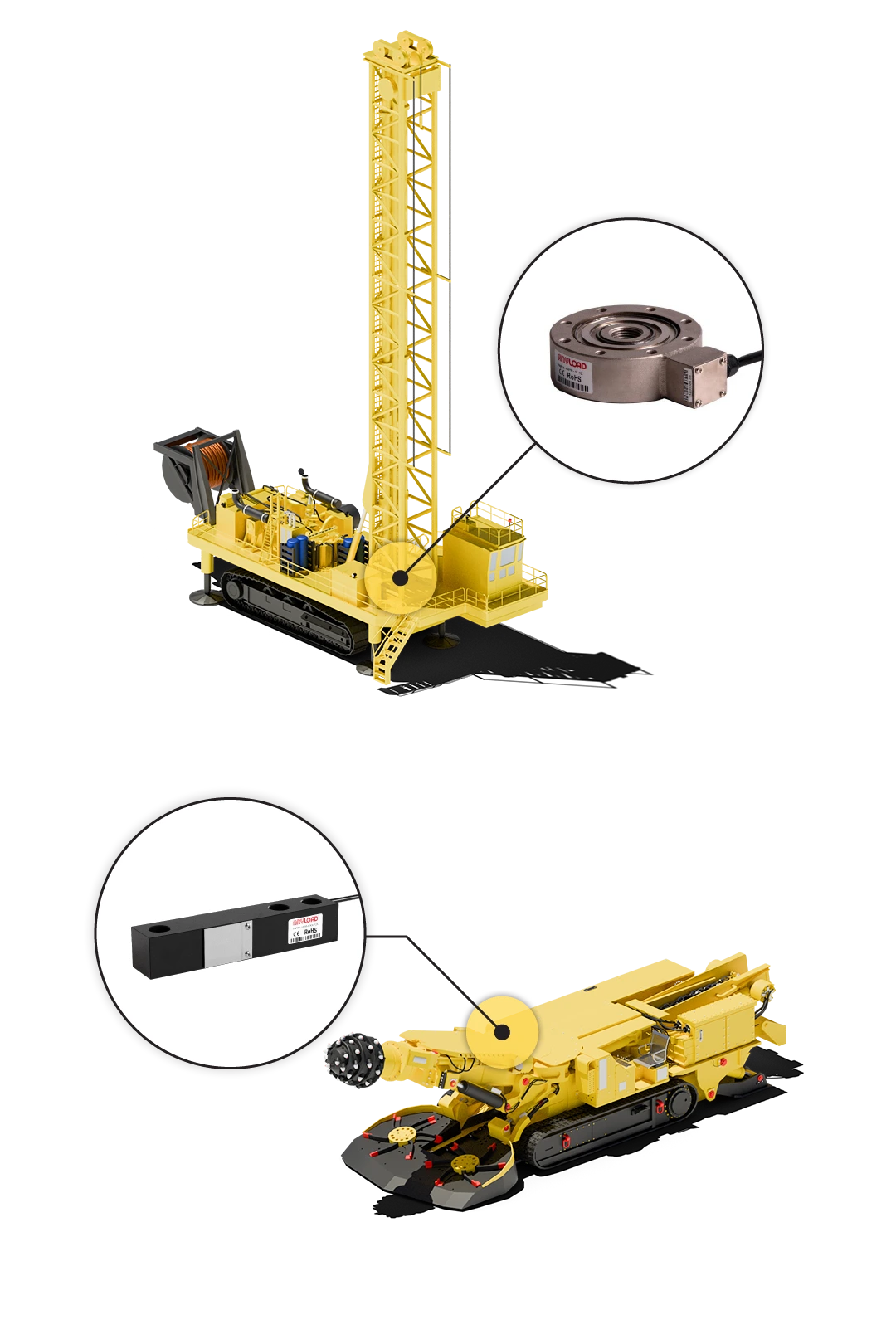

Onboard Weighing

Mechanized and automated mining machinery depends on load cells for payload monitoring, safety assurance, and optimizing operational efficiency. These systems are vital for haul trucks, wheel loaders, drilling equipment, and conveyor systems, ensuring vehicles operate within designed capacity limits, monitor material flow rates, track torque forces, and facilitate accurate loading and unloading in harsh, high-demand environments.

Challenges

- Dynamic Weighing: Mining vehicles, such as haul trucks and loaders, operate on uneven and rugged terrain, requiring load cells that can withstand irregular forces that challenge safety, accuracy, and reliability.

- Harsh Conditions: Onboard weighing systems in mining machinery must withstand extreme conditions, including moisture, corrosive chemicals, abrasive materials, heavy vibration, and significant temperature fluctuations.

- Signal Output: Sensors in mining equipment must deliver measurements in industry-standard formats like CANbus, RS485, or RS232 to seamlessly integrate with existing data acquisition systems (DAQs) and onboard displays.

Solutions

ANYLOAD’s onboard weighing solutions provide mining OEMs with rugged, reliable, and precise weight and force measurement systems. These systems are engineered to endure the extreme conditions of mining environments while offering compatibility with a variety of industry-specific communication protocols, such as CANbus and RS485, ensuring seamless integration with machinery control systems.

View Products:

Hopper & Tank Weighing

Reliable weighing of hoppers, tanks, and vessels is crucial for mining operations, particularly in managing materials such as ore, coal, and chemicals during storage, processing, and batching. These systems are essential for ensuring process efficiency, inventory accuracy, and compliance with operational standards in the mining sector.

Challenges

- Extreme Durability: ANYLOAD products are engineered to operate reliably in high dust/moisture/temperature mining environments. Protective coatings and materials to withstand abrasive and chemically aggressive materials.

- Compliant Products: Intrinsic safety certified (ATEX, IECEx, FM) products with legal-for-trade approvals and other quality certificates to ensure full compliance to regulatory and performance standards.

Solutions

ANYLOAD’s onboard weighing solutions provide mining OEMs with rugged, reliable, and precise weight and force measurement systems. These systems are engineered to endure the extreme conditions of mining environments while offering compatibility with a variety of industry-specific communication protocols, such as CANbus and RS485, ensuring seamless integration with machinery control systems.

View Products:

Torque Measurement

Modern mining equipment relies heavily on torque sensors for performance monitoring, safety, and operational efficiency. These heavy-duty sensors are critical in drilling rigs, rock crushers, bolting machines, and other high-powered equipment, ensuring precise control and measurement of torque under extreme conditions.

Challenges

- High Torque Loads: Drilling and crushing equipment generate immense torque forces that require sensors capable of maintaining accuracy under extreme stress and varying operational loads.

- Harsh Environmental Conditions: Torque sensors must withstand abrasive materials, high vibrations, moisture, and temperature extremes common in mining environments, whether in surface or underground operations.

Solutions

ANYLOAD designs and manufactures heavy-duty torque sensors engineered specifically for the mining industry. These sensors deliver reliable, high-accuracy performance under extreme loads and harsh conditions, ensuring seamless integration with mining equipment systems.

View Products:

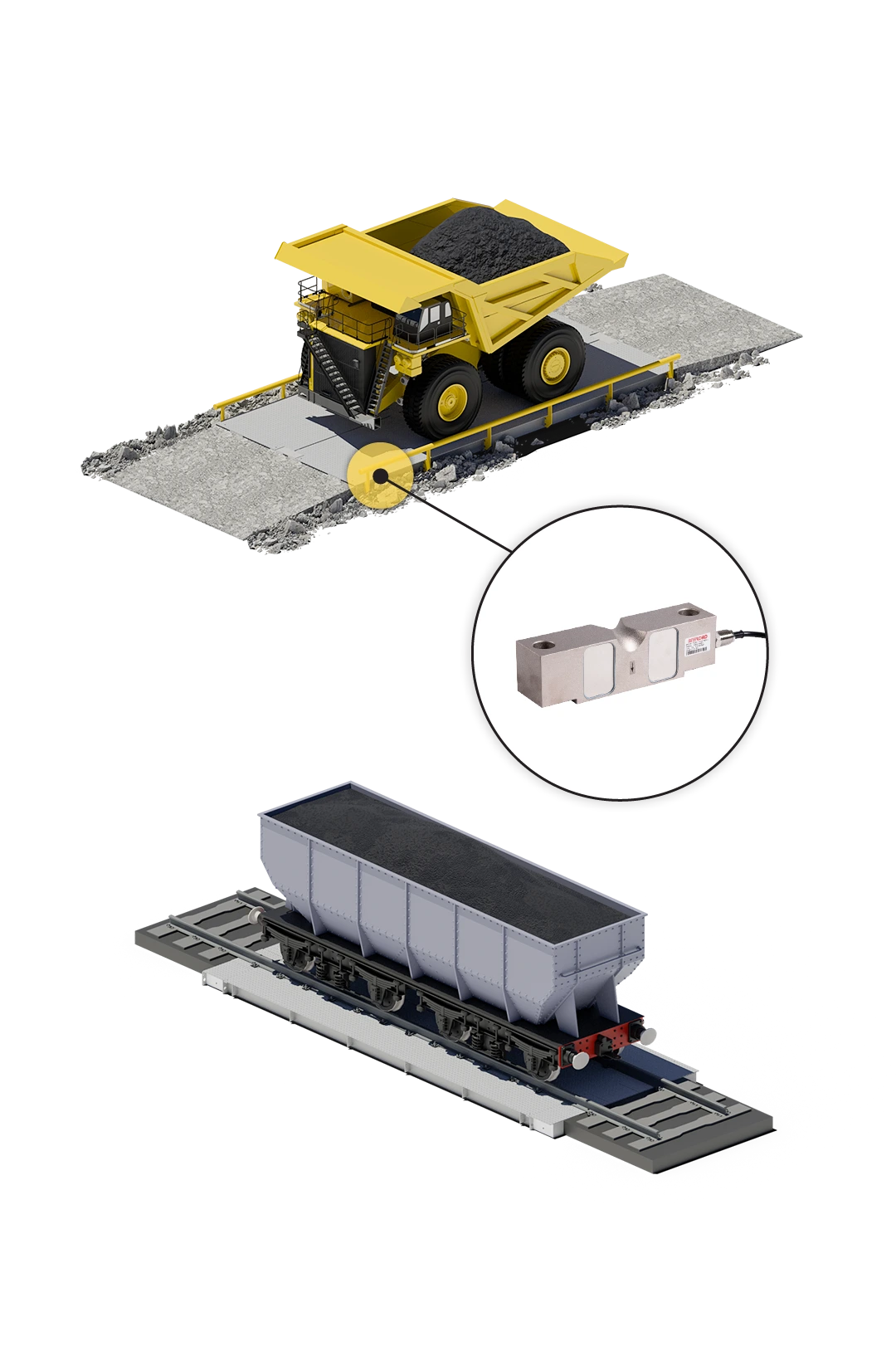

Heavy-Capacity Weighing

Heavy capacity weighing systems, such as truck scales (weighbridges) and rail scales, are essential for managing logistics in mining operations. These systems ensure accurate payload monitoring, optimize transportation efficiency, and support compliance with operational and regulatory requirements.

Challenges

- Modularity and Transportability: Transporting massive weighbridge platforms to remote locations with limited infrastructure is a major challenge. ANYLOAD’s modular designs enable scales to be shipped in standard containers and assembled on-site quickly and efficiently, reducing logistical complexity.

- Durability in Harsh Environments: Mining scales face abrasive materials, extreme dust, moisture, and temperature fluctuations. Our systems are constructed with rugged materials, corrosion-resistant coatings, and sealed load cells to ensure long-term performance and reliability.

- Custom Engineering: Mining sites often require specialized designs to accommodate oversized vehicles, unique site layouts, or specific operational needs.

Solutions

ANYLOAD designs and manufactures heavy-duty torque sensors engineered specifically for the mining industry. These sensors deliver reliable, high-accuracy performance under extreme loads and harsh conditions, ensuring seamless integration with mining equipment systems.

View Products: