- Products

-

-

-

Quick Access

-

-

- Industries

-

-

-

Quick Access

-

-

- Custom Solutions

-

-

- Custom Solutions

-

Our experts will design load cells tailored to your needs.

-

- Custom Request Form

-

From sensitive laboratory equipment to car manufacturing to rocket launching pads, we are up to the challenge.

-

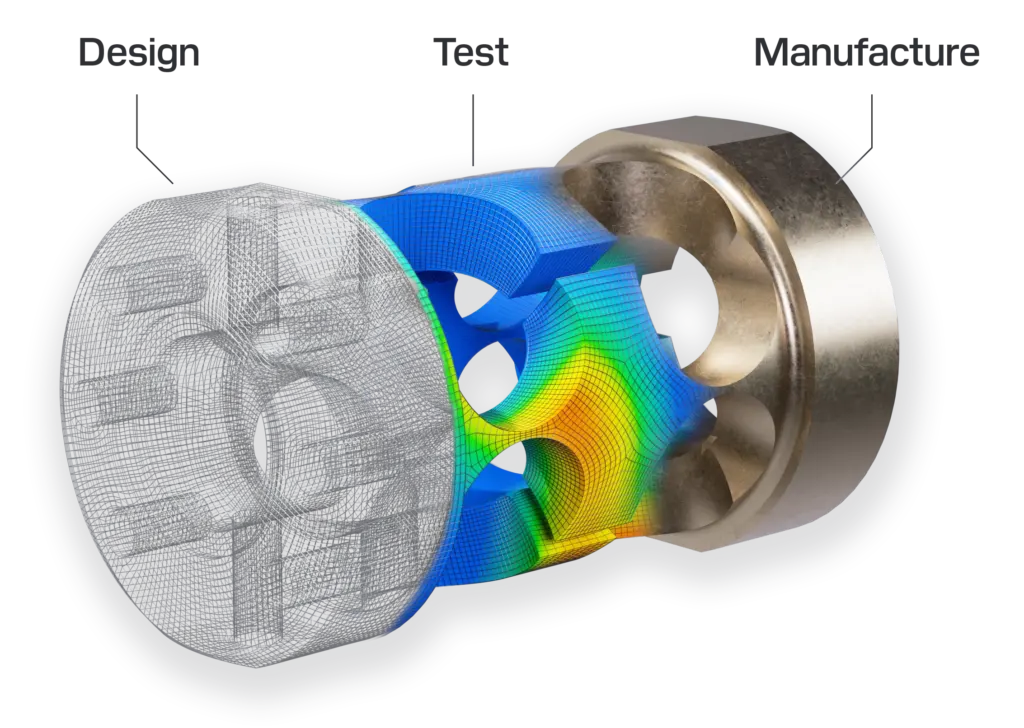

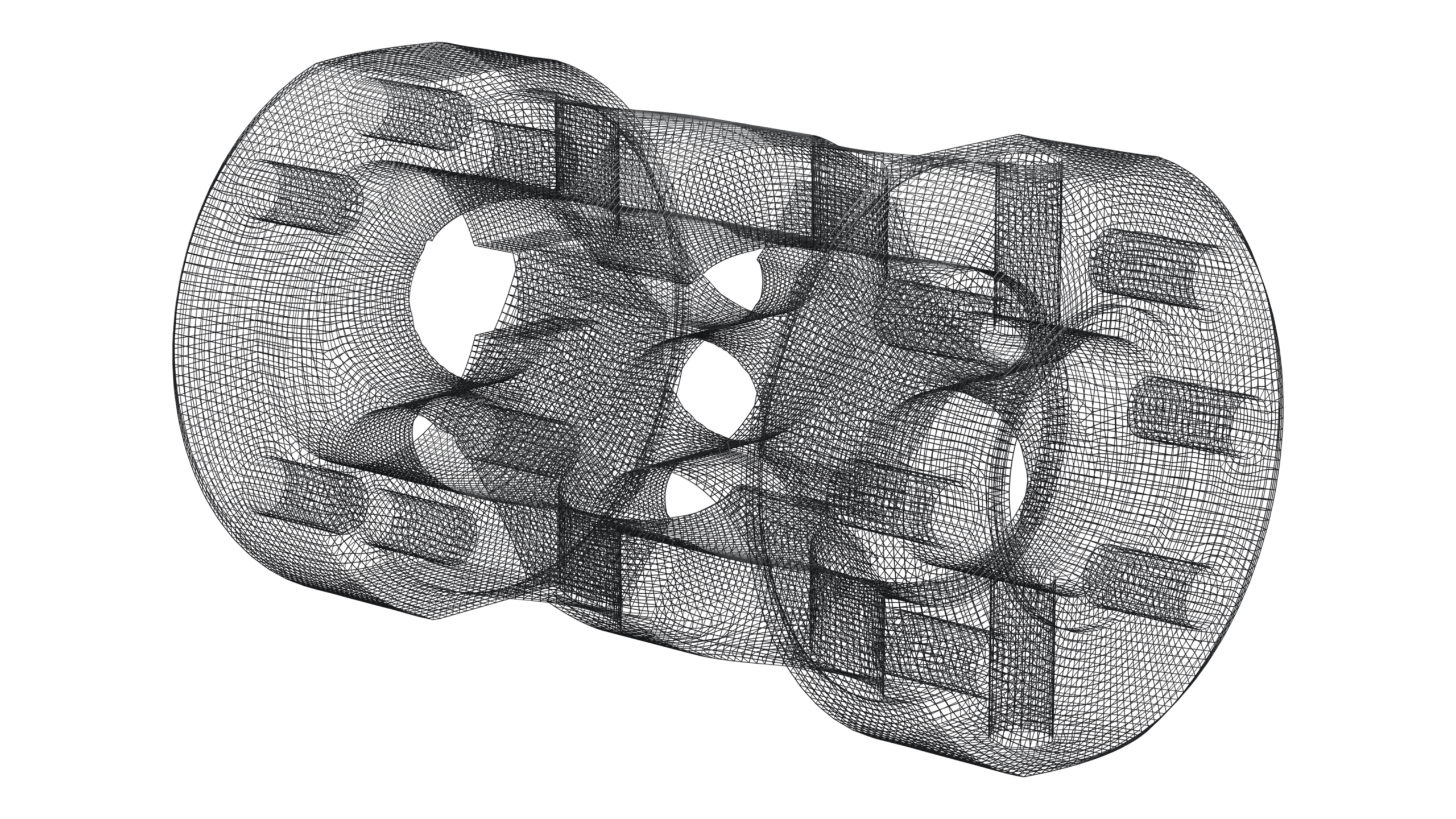

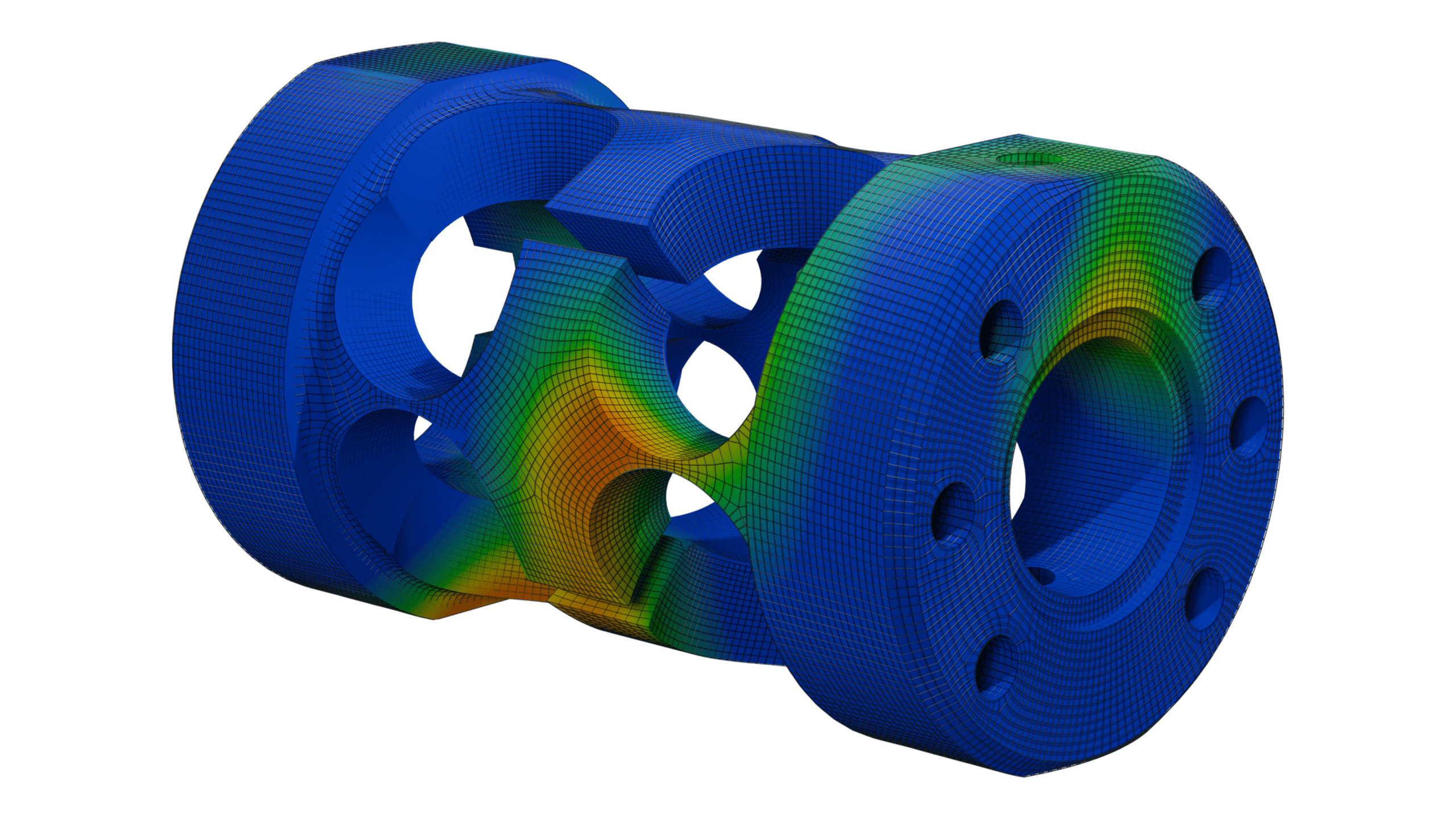

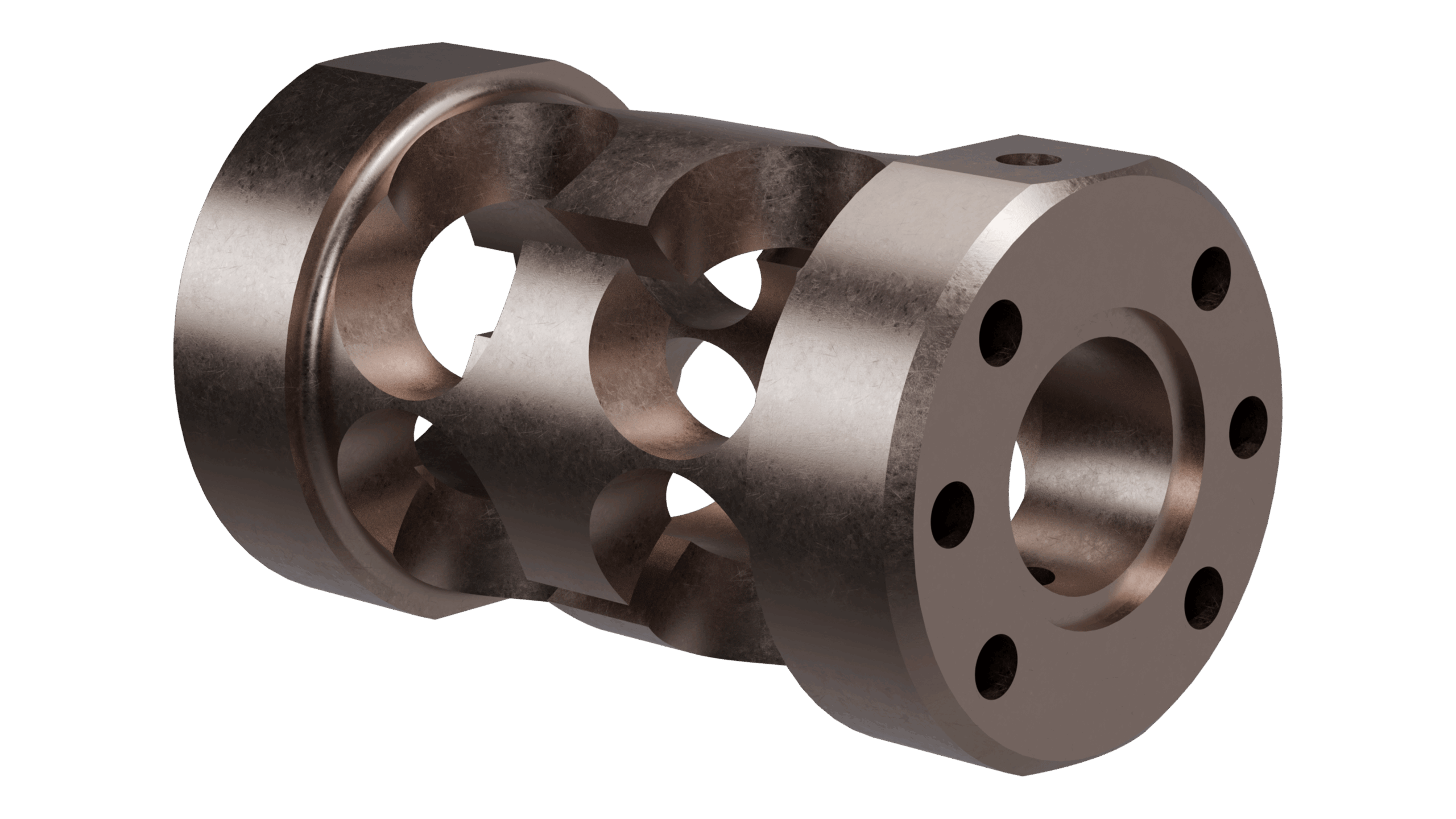

- OEM Design Process

-

Seeking a custom or OEM weighing solution? We can help!

-

-

-

-

Quick Access

-

-

- RESOURCES

-

- Company

-