Weighing System for Poultry Farming

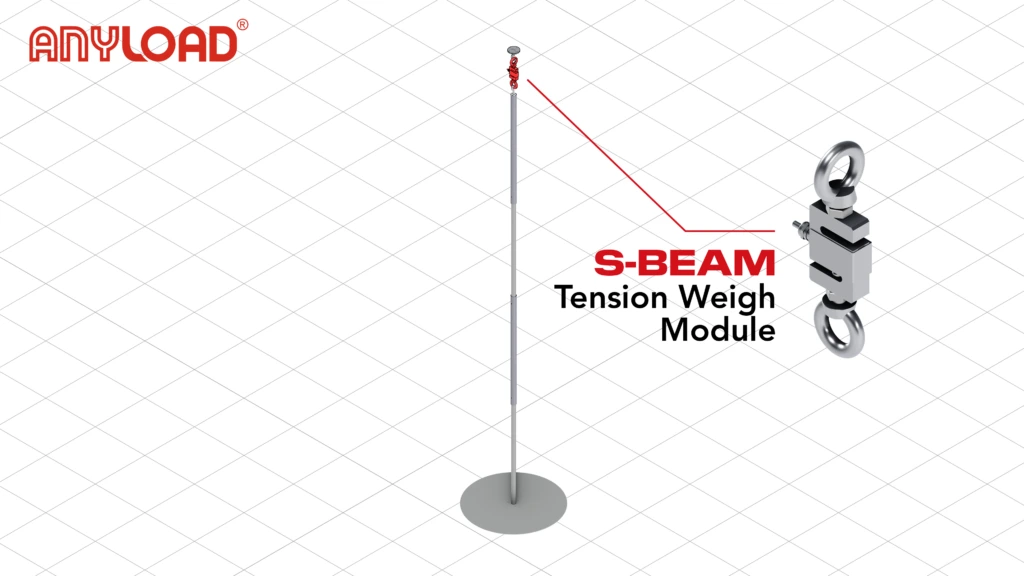

Tension Weighing Solution for Poultry Farming

In poultry farming, it is crucial to closely monitor and track poultry weight and growth, as both overweight and underweight birds can hinder production and reduce farm profitability.

Traditionally, farmers randomly select and weigh poultry at regular intervals and record the data to attempt to monitor growth. However, this method is time-consuming, labor-intensive, and may not accurately represent the average poultry weight.

With these parameters and considerations, we developed a weighing system that automatically and continuously monitors poultry weight, eliminating the need for manual labor. This allows farmers to precisely control feeding and optimize poultry growth.

Challenge

- Poultry is constantly moving. This requires a weighing system with high dynamic precision to accurately measure the birds despite their movement on the scale.

- The weighing system is operating at all times. Long-term stability is essential, as it must maintain high accuracy over time, and withstand changes in temperature and humidity.

- The farms have differing layouts and the height of the poultry also changes as they grow. The system’s weighing platform needs to feature adjustable height to accommodate varying bird heights and farm structures.

Solution

- The weighing system incorporated a multi-joint design with high-precision load cells to accurately weigh poultry even while they are in motion.

- The load cells have undergone extensive testing, including creep, temperature and humidity, and fatigue tests to ensure consistent accuracy in long-term working conditions.

- The weighing system integrated a telescopic rod design for farmers to easily adjust the platform height based on their requirements.

- Additionally, the load cells can be customized with a safety overload of 400% to 500%, to prevent accidental overloading during routine cleaning.

Conclusion

The ANYLOAD poultry weighing system effectively meets farm requirements for precise poultry weight measurement, providing long-term stable and accurate dynamic weighing. The weighing system and platform are designed for straightforward and efficient assembly and setup, enhancing ease of use. Additionally, the weighing platform is available in two corrosion-resistant options: stainless steel and oxidized aluminum, to offer effective protection against erosion from poultry excrement.

Featured Products

101NH

S-Beam Load Cell

See standard version.

- OPTION: Stainless Steel or Alloy Steel

- Threaded mounting holes allow easy mounting to most fixtures

- Versatile design fits wide range of applications

The 101NH S-beam is an OIML C3/C4.5 and NTEP-approved S-beam suited to a wide variety of applications due to its simplicity, ease of installation, and overall reliability. This IP67 water-resistant S-beam is also interchangeable with Rice Lake RL20000, Revere 363, Coti Global CGSB / CSGB-1, and more

EYE

Eye Bolt

See standard version.

- Cast alloy steel

- Includes jam nut

- Imperial thread sizes: 1/4″, 1/2″, M12″

- Metric thread sizes: M12

ANYLOAD eye bolts are used in the assembly of tension weighing applications. Available in imperial and metric threads, the EYE series eye bolts are manufactured from cast alloy steel and are each supplied with a jam nut.

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency