Touchscreen Haptic

Force Sensor

Load Cell for Touch Screen Sensor Technology

With the widespread use of smartphones and smartwatches and the rapid development of display technology, the quality of smartphone LCD screens has become a key concern for consumers. The manufacturing process of LCD screens is complex and precise, making them prone to various defects such as bright spots, dark spots, color deviations, and light leakage. These defects severely impact product display quality.

Therefore, developing high-precision force sensors for automated testing systems is crucial for improving product quality, reducing costs, and enhancing manufacturing processes. Traditional automated testing does not monitor force values, which may lead to damage to the LCD screens or inadequate detection. Utilizing force sensors to monitor testing force values provides a standardized testing approach, thereby improving the efficiency and accuracy of detection across the industry.

Challenge

- How to achieve fast and accurate detection on high-speed production lines.

- How to ensure high-precision detection.

- How to adapt to different sizes and models of LCD screens, ensuring compatibility and versatility.

- How to minimize the product’s size to reduce the overall equipment size and production costs.

- How to ensure the flatness and leveling of the sensor to avoid uneven forces on the LCD screen during testing.

- How to ensure data stability of the sensor during dynamic testing.

Solution

- Sensors are made of high-strength aluminum alloy or stainless steel to ensure stiffness, allowing for a high dynamic response frequency.

- Finite element analysis is used for sensor structural design, calculations, and simulations of actual operating conditions for dynamic analysis and optimization of the sensor structure.

- Interchangeable interface designs enable customers to replace tooling of appropriate size specifications based on the LCD screen size.

- Multi-axis CNC machining is used for one-time processing, ensuring consistency in geometric tolerances.

- Dynamic strain gauges and flexible wires are applied, allowing the sensor to operate stably in dynamic equipment environments.

- A flat design reduces the product’s size while maintaining accuracy.

Conclusion

ANYLOAD’s flat design structure ensures the product height is less than 6.5mm, with a capacity of up to 300kg, and can be customized according to customer height requirements. Testing shows that the product accuracy meets 0.1%FS. The sensor features threaded hole interfaces for easy installation and debugging. The four-beam design ensures product stability.

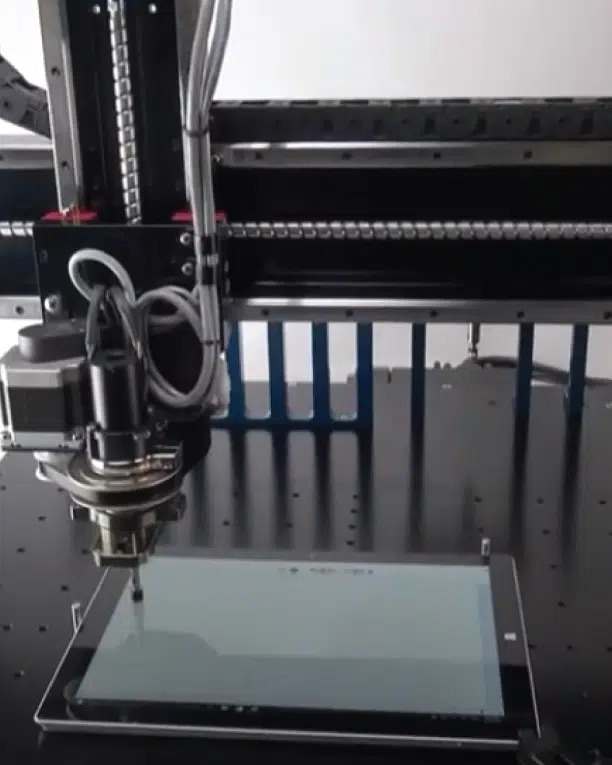

In an automated production line, the 202 series sensors simulate the effect of pressing the screen by hand, enabling rapid functional testing of products. The 202AA series is widely used in automated LCD screen testing for smartphones and smartwatches.

Keywords:

Touch Screen Testing, Force Measurement Sensor, LCD/OLED Touch Sensor Panel Testing, OLED Display Testing, Touch Testing.

Featured Products

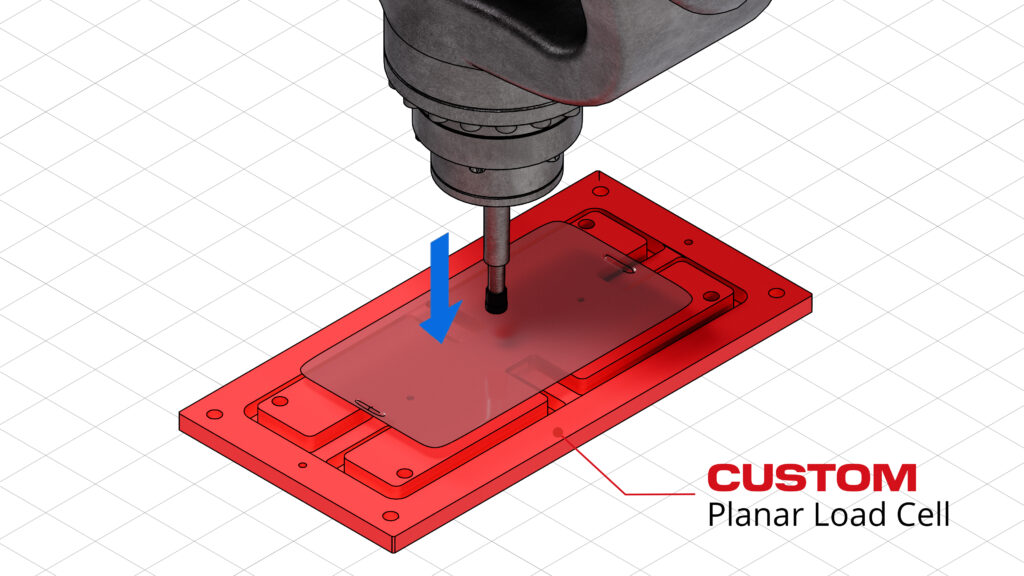

CUSTOM

Planar Load Cell

Request custom solution

ANYLOAD custom planar load cells are designed for low-profile and OEM applications, ideal for platforms, postal scales, medical devices, and other precision weighing systems with limited space and height.

Economically constructed with advanced materials, they deliver reliable, multidirectional force measurements with exceptional linearity and minimal cross-talk, ensuring precise readings for critical applications.

Their compact, flat design allows seamless integration into existing systems, even in confined spaces where traditional load cells are impractical.

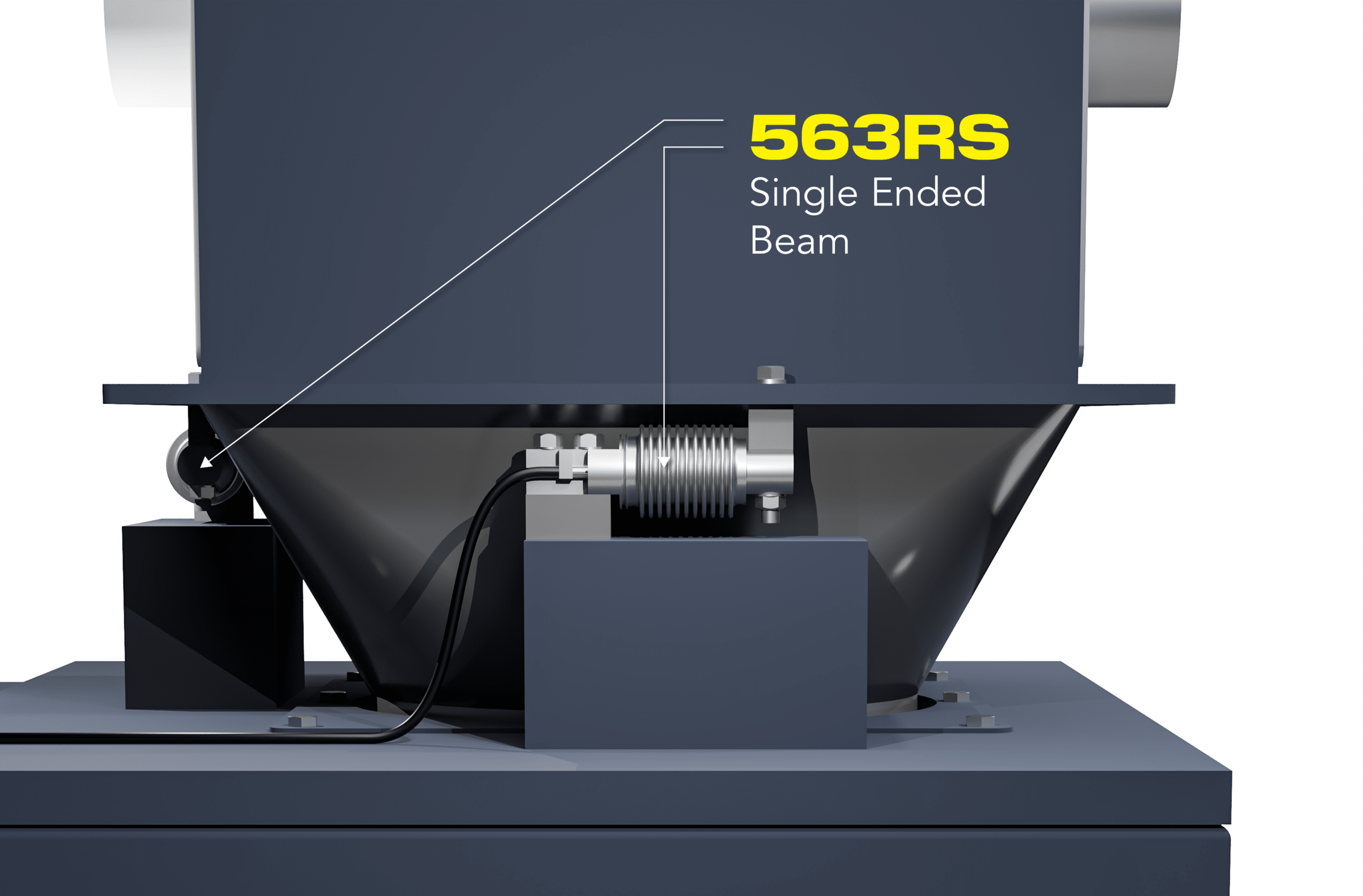

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency