Tea Bag Weighing

Optimizing for Lightweight Precision in High-Capacity Hopper

This equipment is designed specifically for weighing tea bags and is primarily sold to malls, hotels, and supermarket retailers. Tea bags are typically lightweight, weighing around 5g or 10g.

Challenge

- Large Hopper Weight: The tea hopper, which holds the tea prior to bagging, typically weighs about 200g, while each individual tea bag weighs only 5g or 10g.

- Dynamic Weight Inspection: Since this is a dynamic weighing process, weight signals must transmit quickly to the PLC or controller to allow the next action to occur without delay.

- Eccentric Hopper Design: Due to the offset (eccentric) design of the tea hopper, the load cell must handle the torque created by the hopper’s uneven weight distribution.

Solution

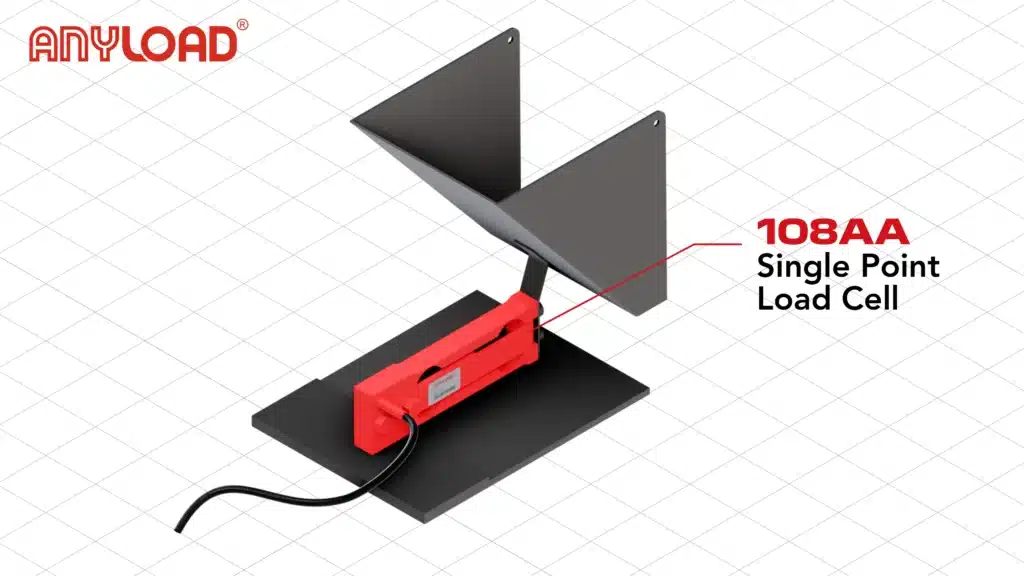

- Our 108AA small-capacity load cells, combined with the A2P-D2 amplifier, offer the perfect solution for this application.

- The 108AA load cell series is specially engineered for applications with high tare weights and small measurement ranges, achieving accuracy levels above 0.023%. The elastomer materials undergo special polishing and inspection, and aerospace-grade vacuum cables are used to enable the sensor to operate in a vacuum environment.

- Constructed with high-strength aluminum, the 108 series sensors provide resilience and overload resistance.

- Finite element analysis optimizes torsion resistance and improves the sensor’s dynamic response time.

- The A2P-D2 amplifier delivers quick and reliable analog signal amplification, eliminating delays common with digital signal processing and allowing immediate integration with the controller.

Conclusion

Integrating the 108AA load cells and A2P-D2 amplifier allows the equipment to measure with precision down to 0.1g. This high accuracy and fast response time enable a more efficient packaging process, significantly boosting production efficiency.

Featured Products

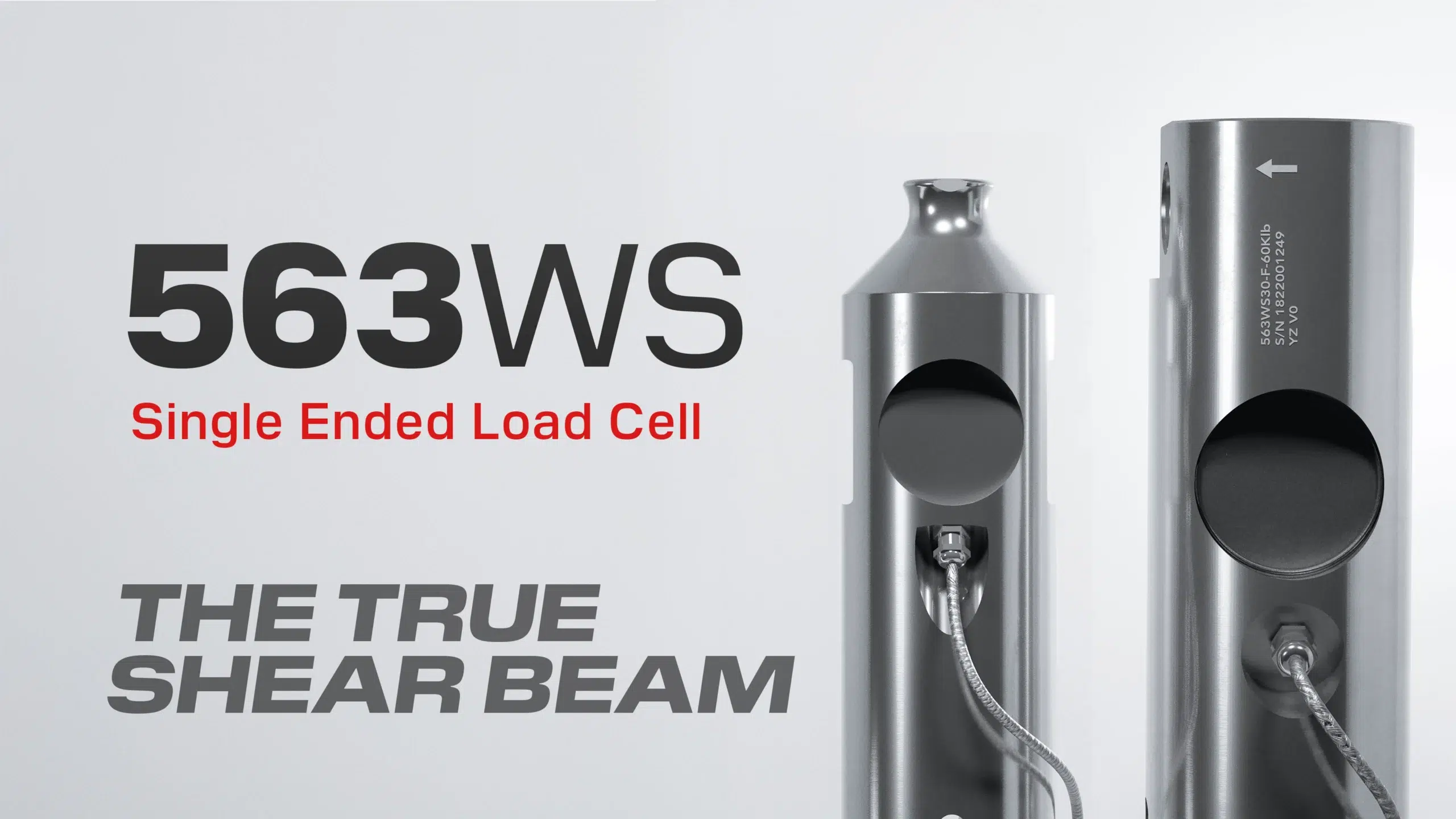

108AA

Single Point Load Cell

See standard version.

- Material: Aluminum, Clear Anodized

- Rated Capacities: 100g, 200g, 300g, 500g, 1kg, 2kg, 3kg, 5kg

- OIML C3 certified from 1kg-5kg

- CE and RoHs certified

The ANYLOAD 108AA single-point load cell delivers reliable weight measurement for light-duty applications. Its aluminum construction offers an ingress protection rating of IP66. This product is available in capacities from 500g to 5kg. All capacities have built-in overload protection to prevent damage.

A2P & A2P-D2

Load Cell Amplifiers

See standard version.

- Drive up to 4×350Ω, 8×700Ω, 8×350Ω load cells through a junction box.

- Fully compliant with the Conformité Européenne (CE)

- Equipped with two options of excitation voltages (5VDC or 12VDC)

ANYLOAD A2P series strain gage amplifiers provide load cell and transducer signal conditioning. The A2P series strain gage amplifiers are DC powered amplifiers that can drive up to 2 x 350Ω load cells connected directly.

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency