Pallet Wrapper Weighing

Load Cell for Pallet Wrapper Weighing Equipment

Pallet wrappers play an important role in transportation and storage of goods in warehouses. Integrating a scale into the pallet wrapper itself streamlines operations by removing the need for an additional weighing process. This weight is crucial to manage shipping weight compliance and load distribution in transit and storage.

Challenge

- Dynamic Weighing: The platform experiences various forces as the pallet is rotated during wrapping, requiring rapid measurement as the load distribution changes.

- High Load Capacity: The pallet wrapper scale must handle loads upwards of 1000kg while maintaining high measurement accuracy.

- Impact and Overload Resistance: Placement of the pallet, if not done carefully can create significant impact loads, so the platform module must be able to meet overload resistance requirements.

Solution

- The sensor uses custom high and low temperature strain gauges, with added temperature compensation and fatigue testing to ensure data stability.

- It incorporates specialized vacuum-sealed materials with excellent electrical insulation, chemical stability, broad temperature range, and low volatility. The elastomer materials undergo special polishing and inspection, and aerospace-grade vacuum cables are used to enable the sensor to operate in a vacuum environment.

- A three-layer sealing system is employed, including strain gauge protection, two layers of vacuum material sealing, and cap sealing. This multi-layer protection effectively prevents moisture from affecting the sensor’s performance.

Conclusion

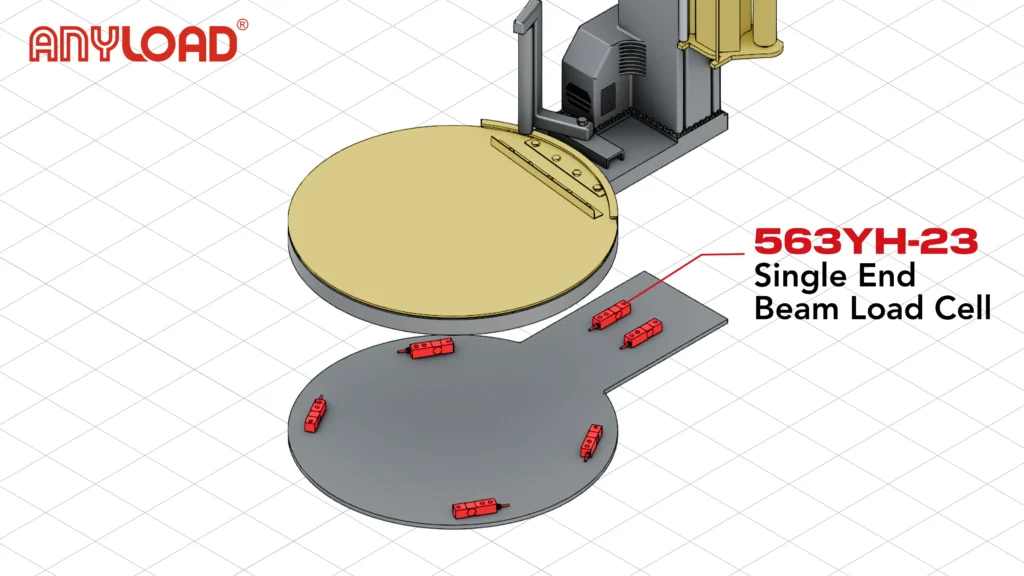

Using six 563YH-23 load cells spaced evenly along the machine platform and base and a J06SS junction box ensures pallets are weighed accurately even with heavily biased weight distribution as the load cell design focuses on torque and off-axis load rejection.

- Constructed with high strength steel alloy or stainless steel, the 563 series sensors offer environmental protection and the resilience required for overload requirements.

- The J06SS junction box allows individual load cell signal trimming, providing excellent corner balance capabilities and a unified analogue signal for integration into a controller.

- Unlike button style load cells, the single shear beam 563YH-23 series load cell can achieve accuracies above ±0.023% while upholding the required overload resistance.

Featured Products

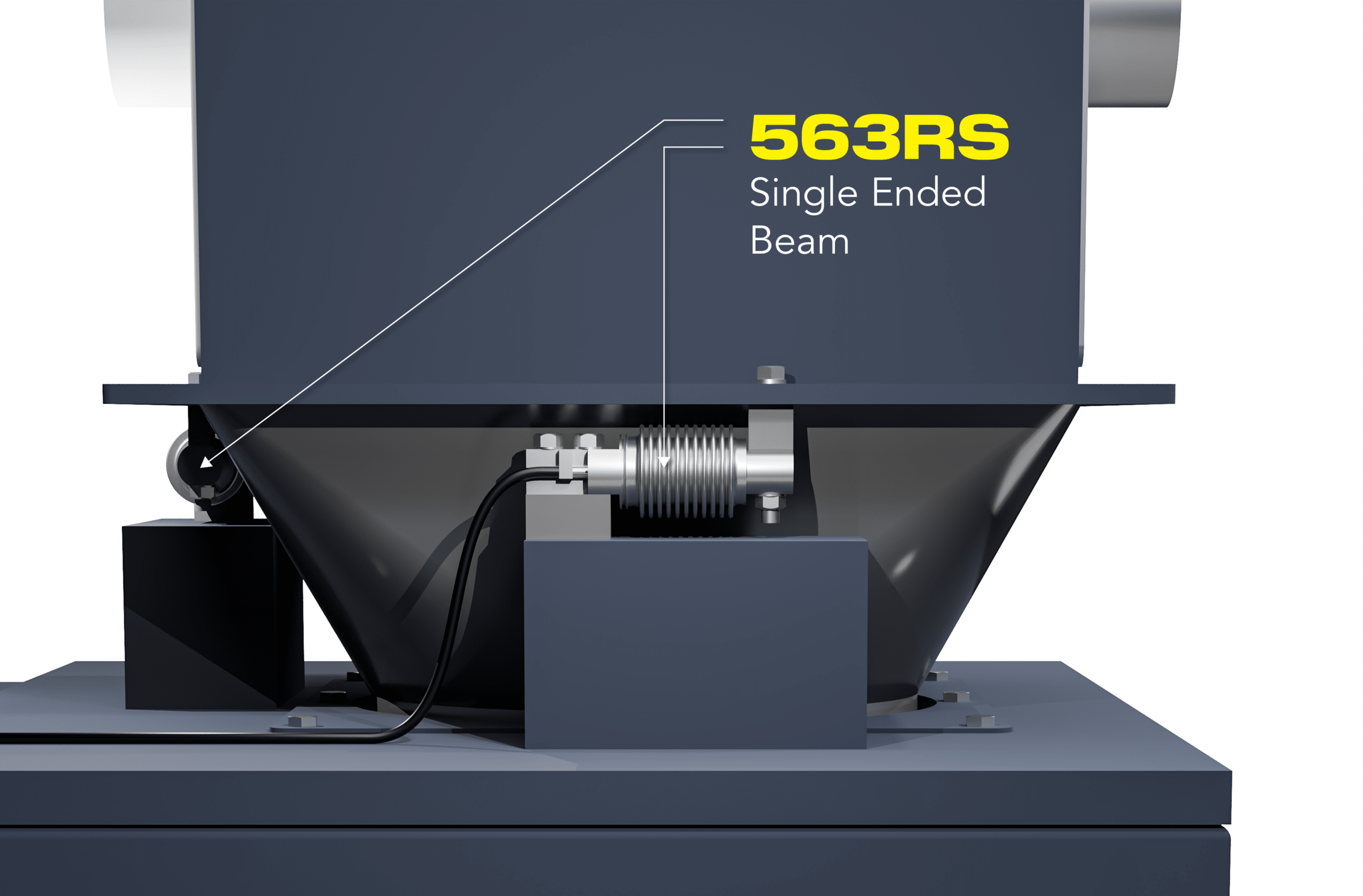

563YH-23

Single Ended Load Cell

See standard version.

- Material: Alloy Steel

- Rated Capacities: 250lb, 500lb, 750lb, 1Klb, 1.5Klb, 2Klb, 2.5Klb, 4Klb, SE5Klb, 5Klb, 10Klb, 15Klb, 20Klb

- CE, RoHS, and Ex certified

Cost-effective and heavy-duty, the 563YH-23 is a single-ended beam load cell. Its low-profile design with IP67 water resistance and high resistance to overload and shock and side loading. This model is popular in higher accuracy applications, including platform scales, pallet scales, process weighing, and more.

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency