Gravimetric Blender

Mixture Weighing

Load Cell for Gravimetric Blenders

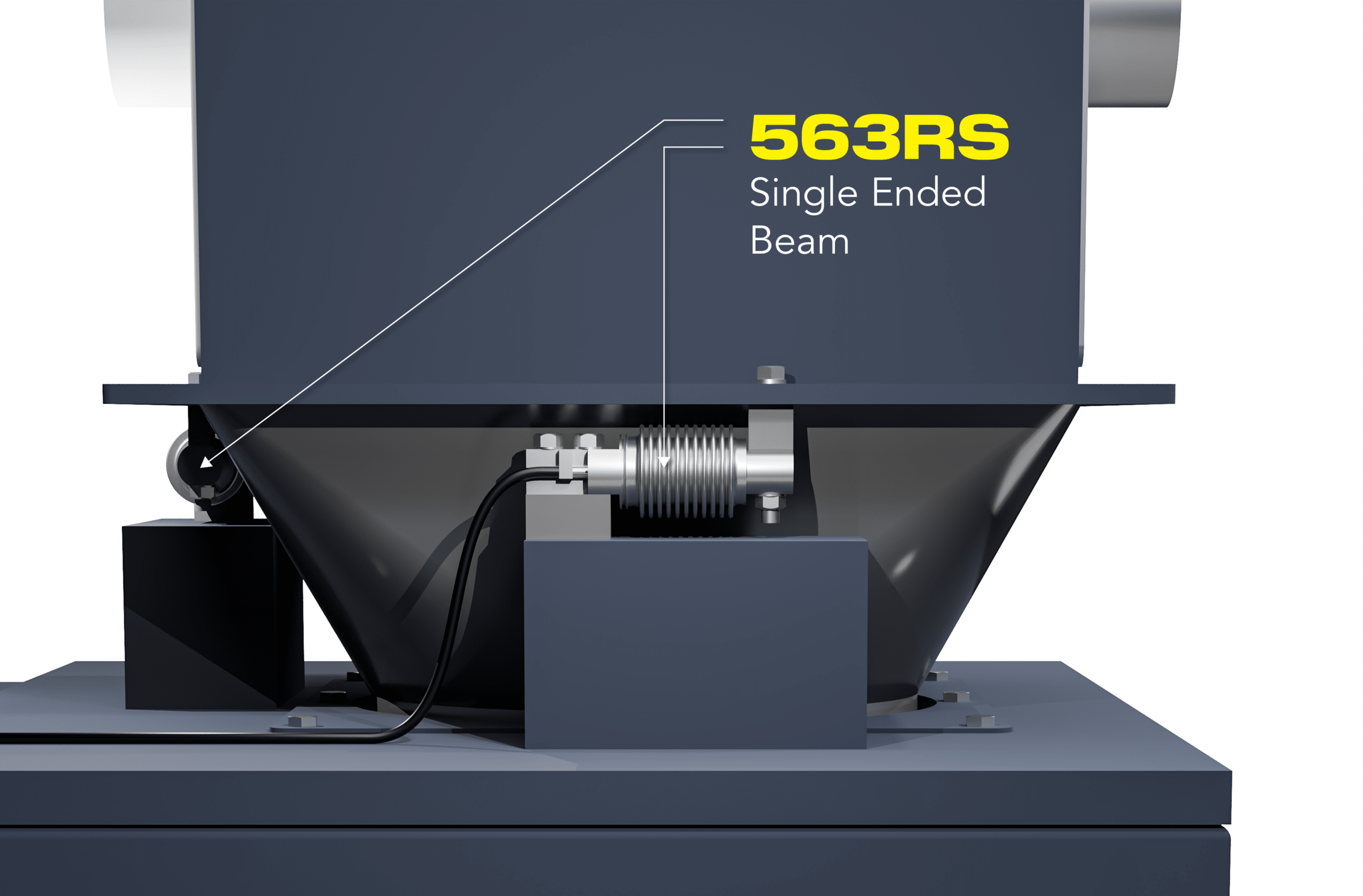

Gravimetric blenders play a crucial role in industries where precisely monitoring the mixture quantities is required, such as in plastics manufacturing or medicinal processing. Being able to accurately meter raw materials such as fine or coarse powders, resin, regrinds, colouring agents, and other additives ensures efficiency and consistency in the output product. The stringent accuracy requirements demand a load cell that excels in off-centre loading and precision weighing of hopper content.

Challenge

- High Accuracy: The system must be able to consistently deliver precise ingredient doses of materials varying in density, constitution, and at variable flow rates.

- Vibration and Impact Management: Load cells must maintain accuracy in a dynamic environment susceptible to disturbance caused by the mixing chamber or adjacent machinery.

- Compact Form Factor: Load cells must mount to the hopper above the blender without exceeding the pre-existing packaging constraints imposed by the machine.

Solution

- The sensor uses custom high- and low-temperature strain gauges, with added temperature compensation and fatigue testing to ensure data stability.

- It incorporates specialized vacuum-sealed materials with excellent electrical insulation, chemical stability, broad temperature range, and low volatility. The elastomer materials undergo special polishing and inspection, and aerospace-grade vacuum cables are used to enable the sensor to operate in a vacuum environment.

- A three-layer sealing system is employed, including strain gauge protection, two layers of vacuum material sealing, and cap sealing. This multi-layer protection effectively prevents moisture from affecting the sensor’s performance.

Conclusion

- Ensures ±0.03% accuracy for consistent mixtures and efficiency.

- Compact design maximizes vertical space, minimizes horizontal area, and fits diverse hopper designs.

- Handles eccentric loading effectively.

- Constructed with high-strength aluminum alloy for durability, vibration resistance, and cost-efficiency.

- Single-point design eliminates the need for junction boxes, enabling easy installation with accurate readouts.

- Optimized structural aspect ratio enhances torsion resistance.

Featured Products

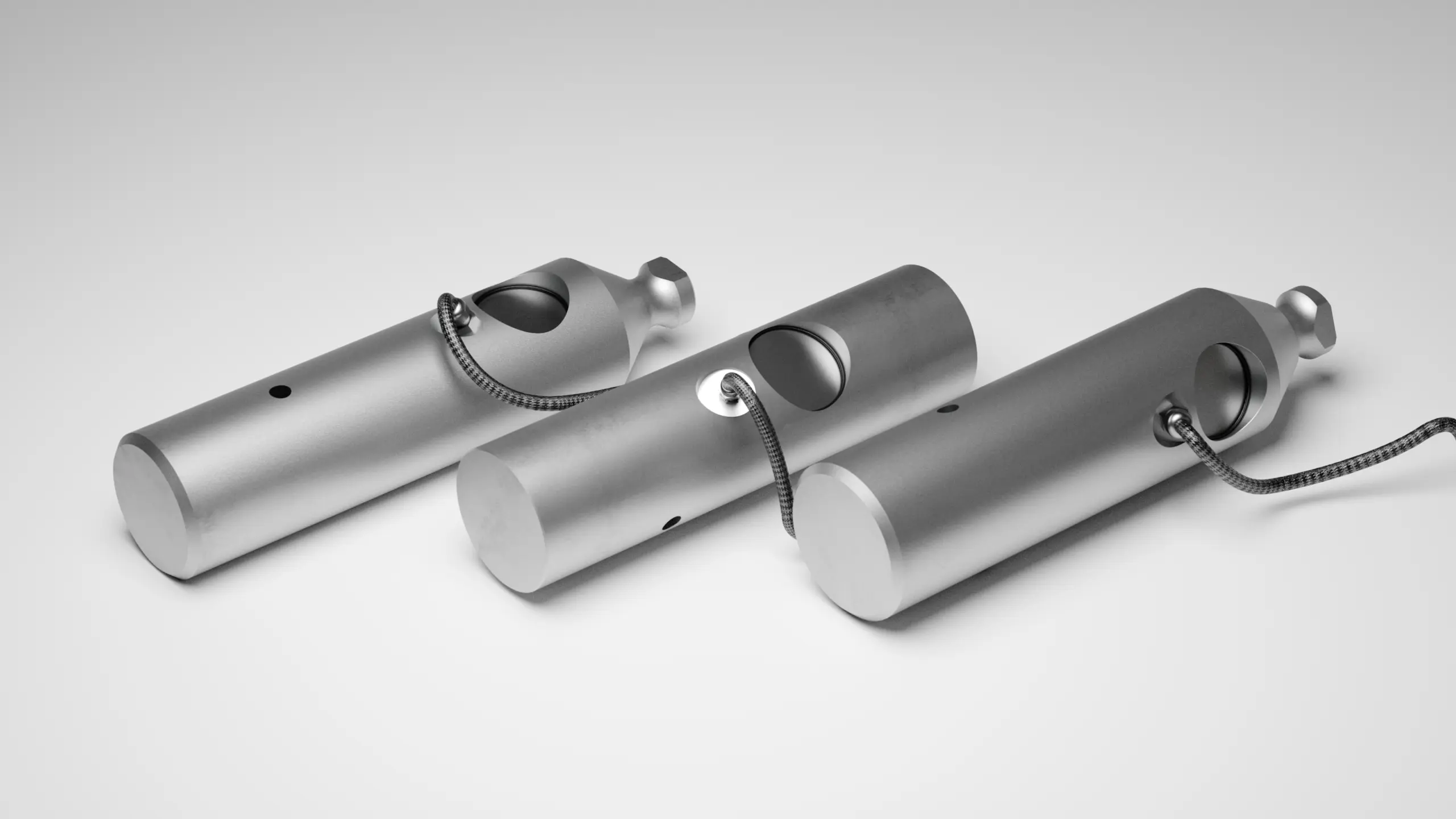

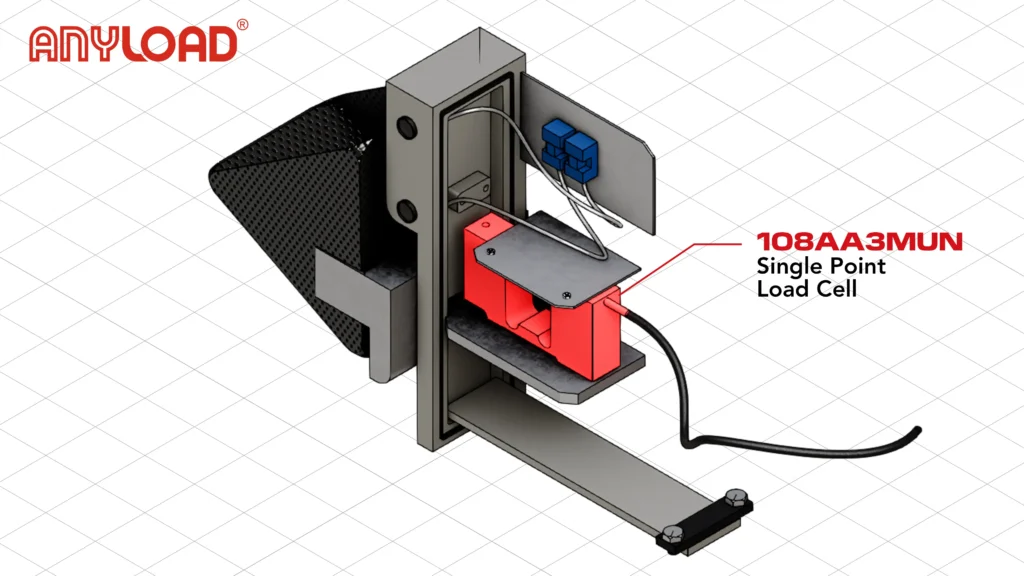

108AA3MUN

Single Ended Load Cell

See standard version.

Offering superior value and reliability, the 108AA3MUN is a robustly designed single-point load cell popularly used in packaging scales and other direct mounting applications. The 108AA3MUN is interchangeable with Vishay Tedea-Huntleigh 1010/1015.

- Material: Aluminum, Clear Anodized

- Rated Capacities: 3kg, 5kg, 10kg, 15kg, 20kg, 30kg, 50kg, 90kg

- Full Scale Output: 2mV/V ± 0.25%

- Safe Overload: 150% of full scale

- Breaking Overload: 300% of full scale

- IP Rating: IP66

- CE and RoHS certified

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency