Chemical Tank Weighing

Tank Weighing Load Cell & Weigh Module

ANYLOAD load cells are integrated into a chemical manufacturing facility in high temperature and corrosive environments to provide critical weight information to control processes, including batching, inventory management, and safety compliance within the chemical industry.

How it works:

- Accurate weight measurement of chemical reactor vessels is crucial for optimizing production processes, ensuring quality control, and maintaining safety standards.

- During chemical processing, precise control over the input and output of materials is essential to maintain product consistency and to comply with industry regulations.

- In the plant depicted, large-scale reactor vessels are integral to the chemical production process. These vessels handle various reactions under controlled conditions, requiring precise weight monitoring to manage the flow of reactants and products effectively.

- A reliable and low-profile weighing solution is required to integrate seamlessly with the existing reactor vessel infrastructure without significant alterations.

- ANYLOAD 102DS load cells and accompanying M3 mounts are installed at the base of the reactor vessels, providing continuous and accurate weight measurement throughout the production cycle.

Key Features

- Precision Process Control: Load cells facilitate the precise control and monitoring of reaction processes required by in the chemical industry by providing constant and reliable weight measurements.

- High Safety Factor: The load cells supplied were built to be intrinsically safe, ensuring that this electrical equipment can safely operate in hazardous environments without the possibility of sparking an ignition. Mechanically, the 102DS load cell and M3 mounting system are also very resilient, with high safety factors and sideload and uplift protection.

- Heat & Corrosion Resistance: The stainless steel mount and load cells customized with heat-resistant strain gauges and welded sealed are highly effective in maintaining reliable performance in a challenging environment.

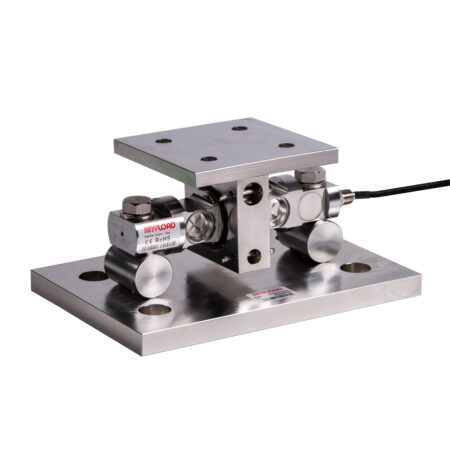

102DSM3

Weigh Module

See standard version.

- Simplifies design, installation, and maintenance

- Uplift and sideload protection

- Stainless steel – corrosion resistant

- Designed to compensate against thermal expansion changes

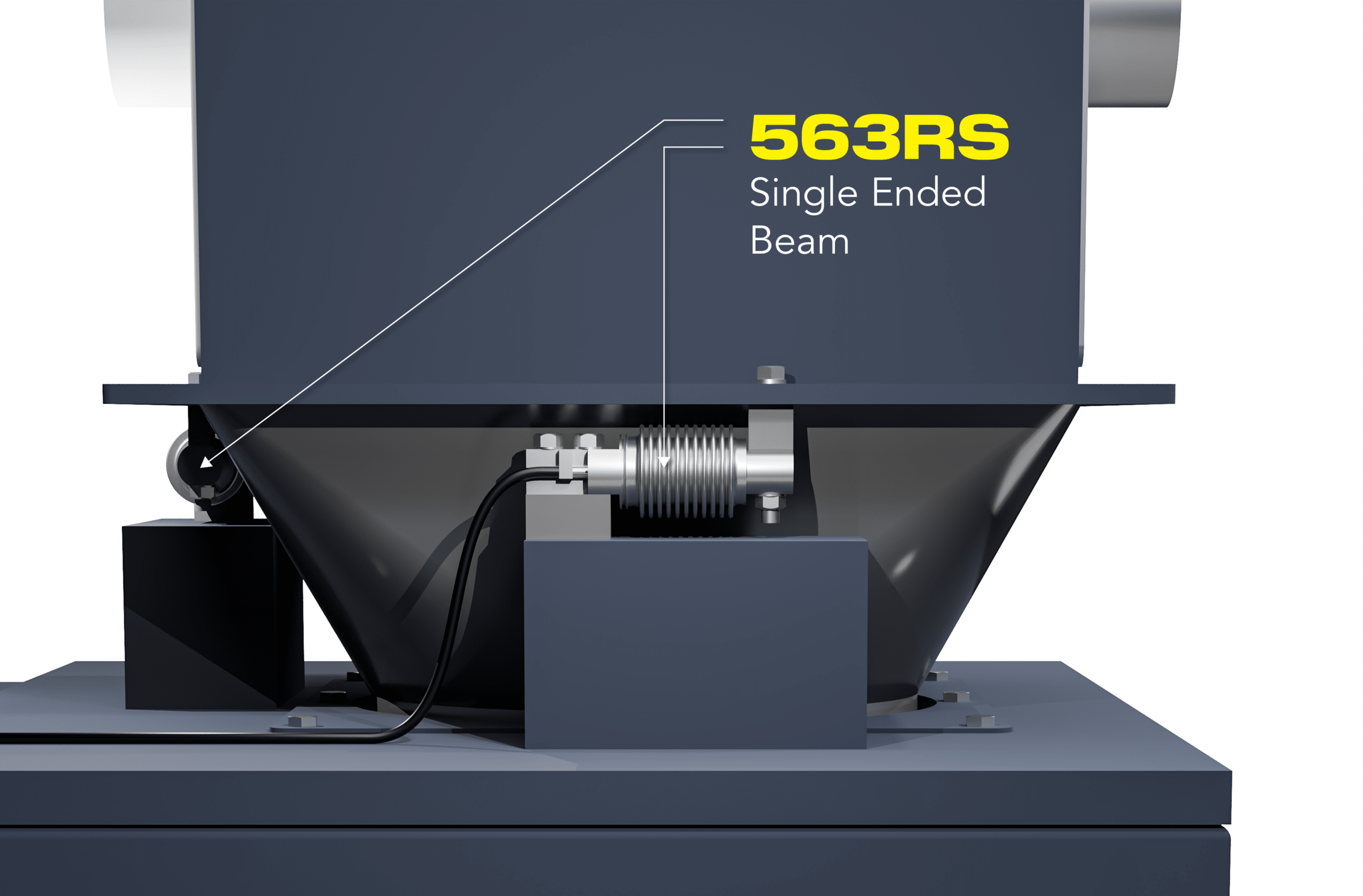

102DS-25Klb-EX

Double Ended Shear Beam

See standard version.

- Overload resistant (up to 150% of FSO safe overloading)

- Intrinsically safe load cell (FM, ATEX, IECEx)

- Custom high temperature resistance and compensation

- Legal for trade tank weighing load cell (NTEP, OIML)

Explore Case Studies

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency