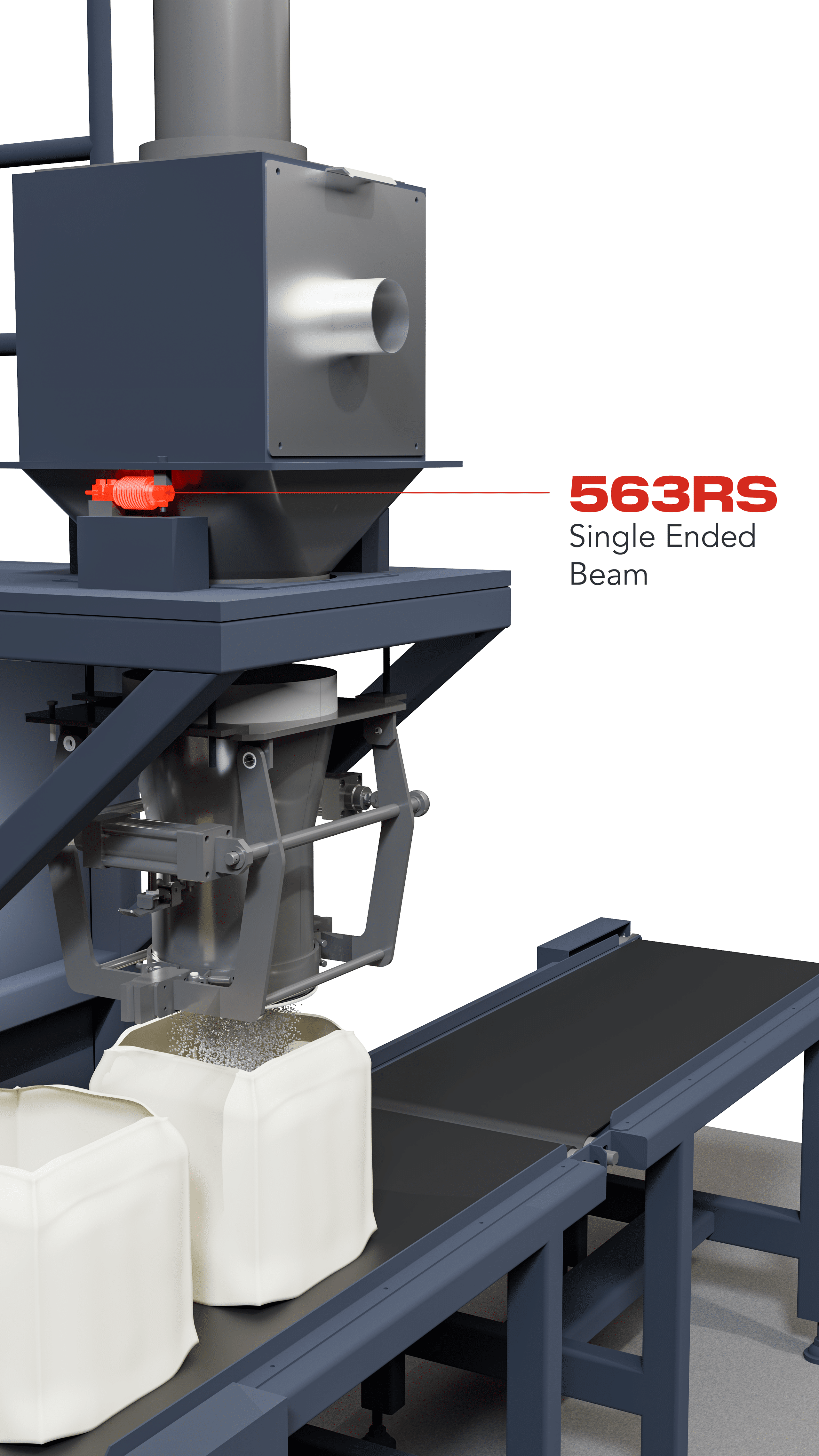

Bag Filling Machines

Bag filling and other process weighing and control systems require high precision load cells that also have fast response times to ensure maximal efficiency when portioning materials.

How it works:

- Process control equipment depend on high performance load cells to ensure that the correct portions are distributed.

- The filling hopper has 3-4 load cells installed to monitor the weight of the load at a high frequency to ensure fast response times.

- The process control system can precisely control filling to minimize over/underfilling.

- When the filling hopper has a sufficient portion of product, a relay triggers it to empty into the container below.

Custom Solution

Load cell sensors allow precise control of the automation process, improve product consistency, and provide operational efficiency. ANYLOAD load cells allow for process control systems manufacturers and operators to maintain a high speed of portioning and filling without compromising on accuracy in weighing.

Featured Products

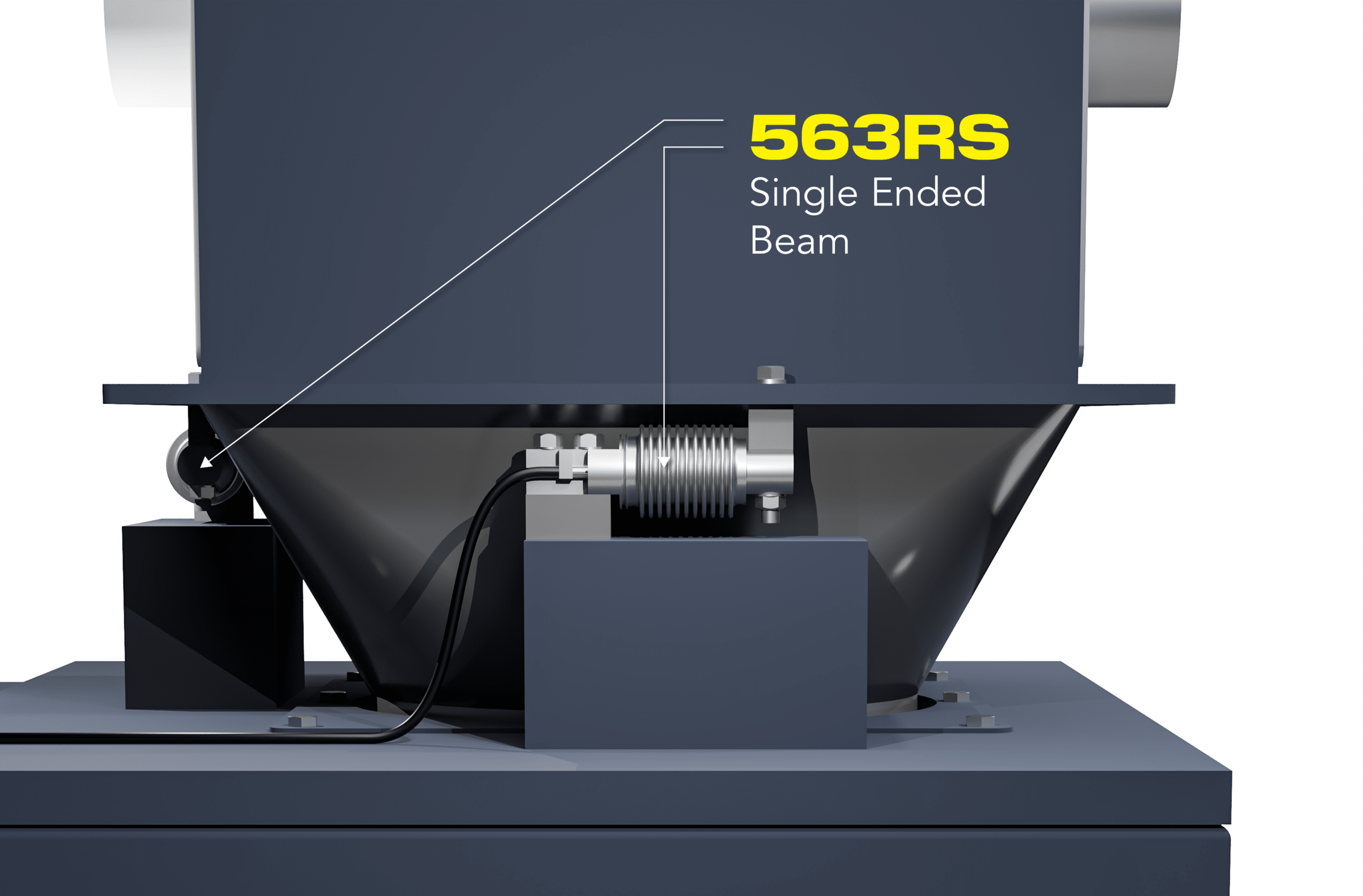

563RS

Single Ended Beam

See standard version.

- Compact, low-profile design

- IP68 washdown water- and corrosion-resistant stainless steel

- Simple installation

The time-tested 563RS delivers a high degree of reliability and versatility for industrial process control and weighing needs, especially in powder & bulk filling, conveyer weighing, and other process weighing applications.

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency