Ancient Canoe Weighing

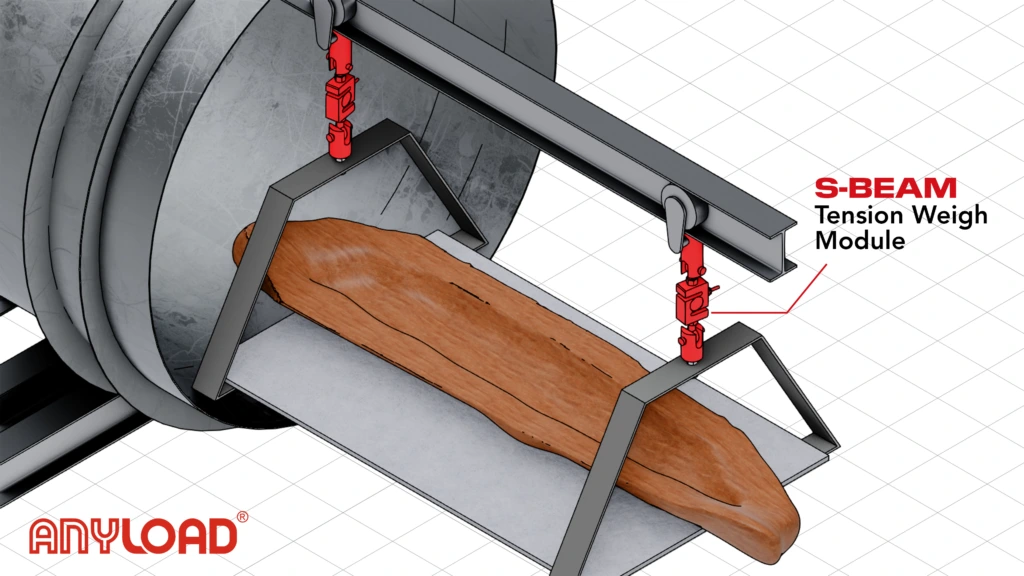

Tension Weigh Module for Ancient Canoe Restoration

With the continuous advancement of archaeology, the excavation, restoration, and preservation of ancient artifacts have become increasingly important, especially in underwater archaeology and the excavation of ancient boats. A 5,000-year-old canoe was discovered in the Liangzhu Cultural Village, a significant cultural heritage with immense historical and archaeological value. However, its excavation, preservation, and restoration present multiple risks and challenges.

Challenge

- The sensor must operate continuously in temperatures ranging from -40°C to +90°C, requiring data stability over prolonged exposure to extreme temperatures.

- It needs to function in a vacuum environment, ensuring that the sensor’s performance remains unaffected by the vacuum conditions.

- It must withstand high humidity, requiring the sensor to resist moisture and avoid any impact on performance.

Solution

- The sensor uses custom high- and low-temperature strain gauges, with added temperature compensation and fatigue testing to ensure data stability.

- It incorporates specialized vacuum-sealed materials with excellent electrical insulation, chemical stability, broad temperature range, and low volatility. The elastomer materials undergo special polishing and inspection, and aerospace-grade vacuum cables are used to enable the sensor to operate in a vacuum environment.

- A three-layer sealing system is employed, including strain gauge protection, two layers of vacuum material sealing, and cap sealing. This multi-layer protection effectively prevents moisture from affecting the sensor’s performance.

Conclusion

In the future, we aim to further enhance the performance of strain-based load cells in specialized environments, providing crucial support for broader applications.

Featured Products

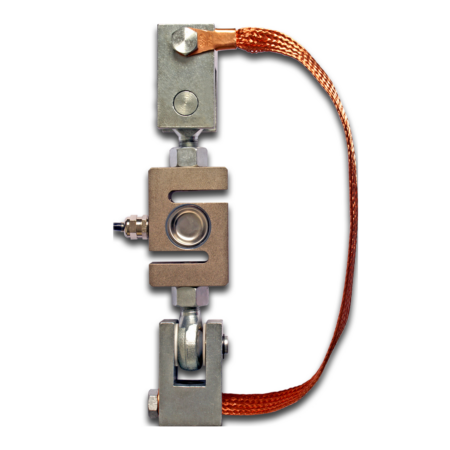

101NH

S-Beam Load Cell

See standard version.

- OPTION: Stainless Steel or Alloy Steel

- Threaded mounting holes allow easy mounting to most fixtures

- Versatile design fits wide range of applications

The 101NH S-beam is an OIML C3/C4.5 and NTEP-approved S-beam suited to a wide variety of applications due to its simplicity, ease of installation, and overall reliability. This IP67 water-resistant S-beam is also interchangeable with Rice Lake RL20000, Revere 363, Coti Global CGSB / CSGB-1, and more

101NHM2

Tension Weigh Module

See standard version.

- Material: Alloy Steel and Stainless Steel

- Capacity: 50lb-10Klb

- Stray currents can go through the grounding strap bypassing the load cell

- Allows for high accuracy tension loading

The 101NHM2 install the bottom rod end bearings & clevises 90 disposed from top set to achive better performance.

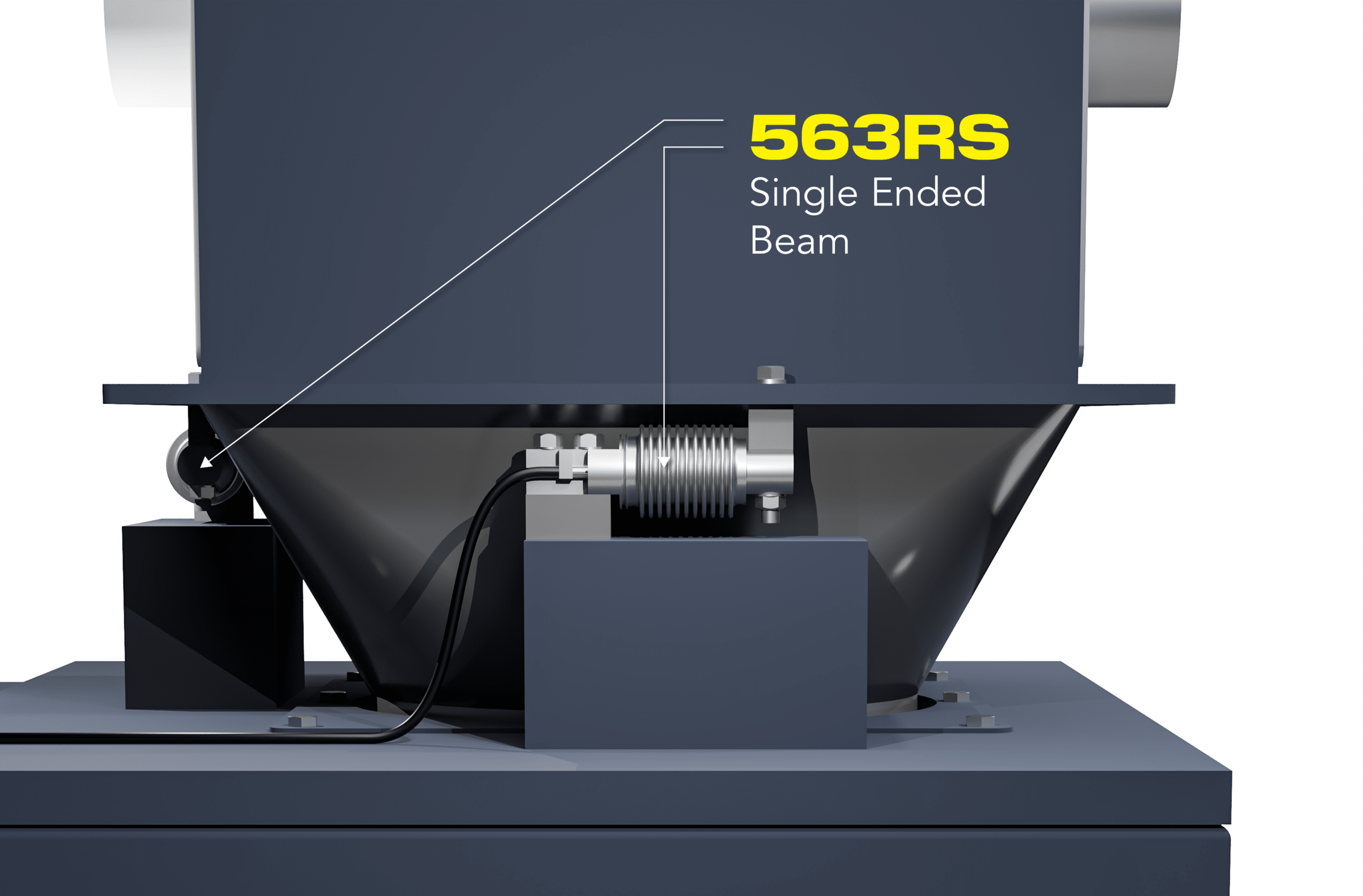

Agricultural Weighing Solutions

How agricultural industry uses our load cell for cart and mobile equipment for optimal result

Increase Turbine Life Span

Gravimetric quality assurance solution for wind turbine blades studies

Bag Filling Machine Load Cells

Bag filling and other process weighing and control system for maximal efficiency