Quality Assurance

At ANYLOAD, certified to ISO9001:2015 and VCAP standards, we understand that crafting precision load cells for demanding environments across the globe is a testament not just to engineering excellence, but to a relentless pursuit of quality. Our company ethos is built on a foundation of Continuous Improvement, Investment in People, and Open Dialogue.

Continuous Improvement We embrace the philosophy of continuous improvement as a core principle.

Continuous Improvement We embrace the philosophy of continuous improvement as a core principle.

Our journey towards quality is never-ending. We embrace the philosophy of continuous improvement as a core principle. Every process, every product, and every service is seen as an opportunity for refinement and enhancement. This relentless pursuit ensures that we not only meet but exceed the stringent standards expected by our clients and regulatory bodies.

Investment in People Our greatest asset is our team.

Investment in People Our greatest asset is our team.

Our commitment to excellence extends beyond our products and services to the heart of our organization—our people. We believe in investing in our team members as a fundamental principle. Every training session, every development opportunity, and every support initiative is seen as a chance to nurture talent and foster growth. This unwavering dedication ensures that our workforce is not only skilled and knowledgeable but also empowered and motivated, driving us to surpass the expectations of our clients and achieve outstanding results.

Open Dialogue Transparency and communication are the cornerstones of our quality assurance process.

Open Dialogue Transparency and communication are the cornerstones of our quality assurance process.

Our dedication to excellence is mirrored in our commitment to open dialogue. We foster a culture where every conversation, every piece of feedback, and every idea is valued and respected. By encouraging transparent and honest communication, we create an environment where collaboration and innovation thrive. This open exchange ensures that we not only address challenges swiftly but also continuously evolve, meeting and exceeding the expectations of our clients and stakeholders.

Manufacturing Excellence

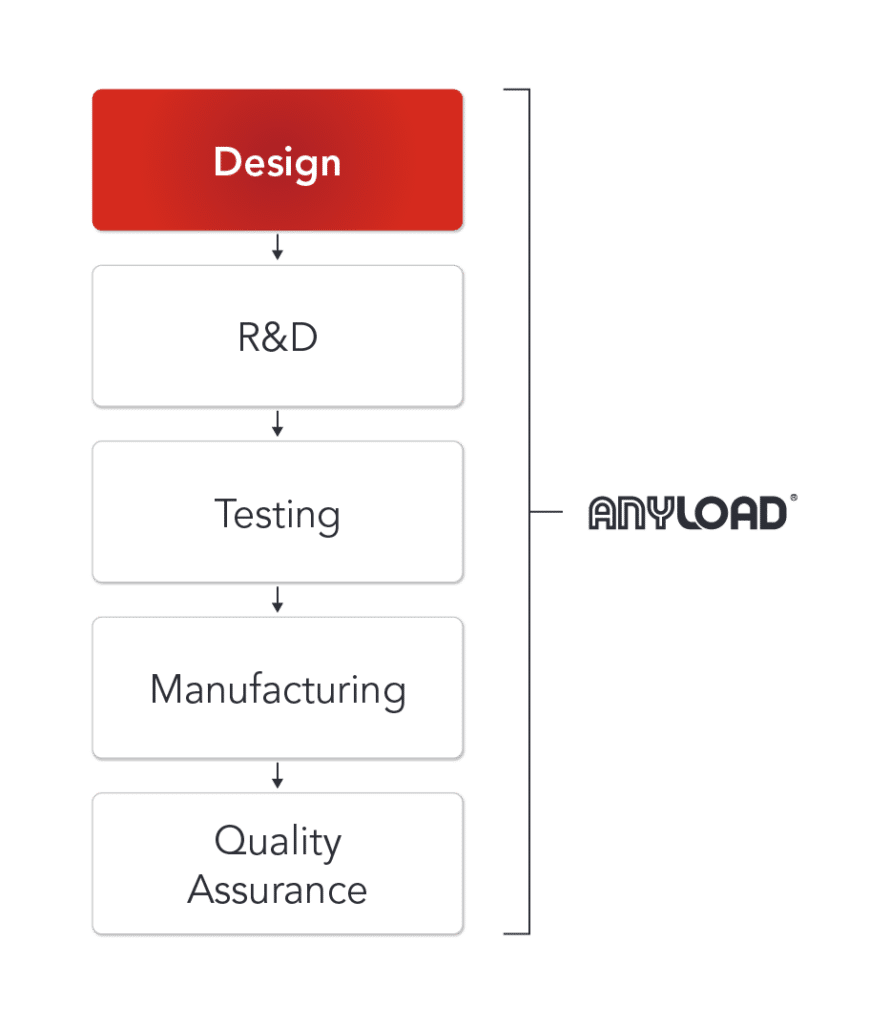

Manufacturing tens of thousands of precision load cells annually is a significant challenge—one that ANYLOAD meets with unwavering dedication to quality. We employ a trio of core principles that ensure our operations not only meet but exceed industry standards:

Vertical Integration: By vertically integrating our operations, we have full control over every stage of production, from design and development to manufacturing and distribution.

Go and See: True understanding stems from firsthand experience, which is central to our approach to quality assurance. Our team not only actively engage in on-site evaluations from the factory floor to the final field application but also eagerly solicit and incorporate feedback from our customers.

Supplier Relations: The quality of our products is a reflection of the quality of our components. We cultivate strong, collaborative relationships with our suppliers. Through rigorous vetting and continuous partnership, we ensure that every component in our supply chain upholds the high standards that ANYLOAD is known for.

Quality Managment System

Our company and products are accredited to numerous internationally-recognized industry standards, including but not limited to:

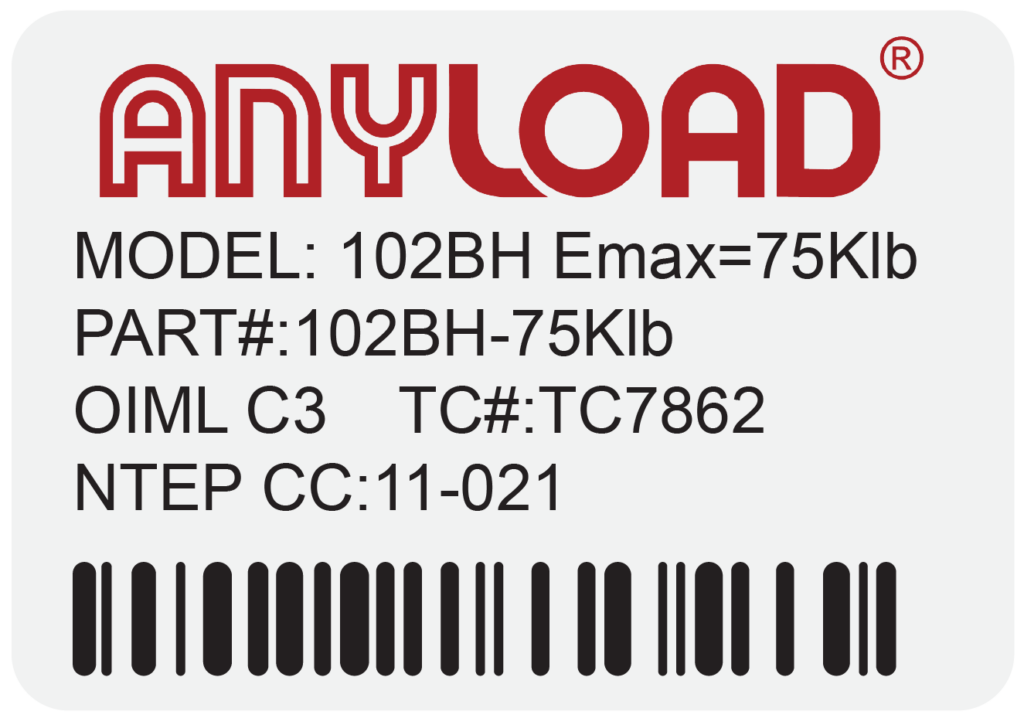

To achieve a comprehensive quality management system, we developed a sophisticated barcode system in order to track each product. Our system internally records numerous key pieces of information to constantly track and improve performance:

Much of this information can be promptly retrieved and shared with our partners in the event of a support ticket or QA event.

Barcode System

- Name of the operator for each procedure (bonding, wiring, corner adjustments, etc.

- Main components (strain gage, load cell element, PCB, etc.)

- Date and time of each procedure

- Test records

- Calibration certificate

- Additional notes from the QA department

- Shipping date

- Customer Information (for warranty purposes)

Testing Equipment

All testing is performed by our experienced quality control team at our own in-house facilities with cutting edge testing equipment.

As part of our commitment to providing reliable and high quality products, we perform temperature tests from -10°C to 50°C as well as perform overload tests on every single load cell we produce to ensure that our load cells function in all types of environments and applications.

We continuously invest in expanding and improving our in-house R&D, calibration, and QA testing capabilities through the purchase of new equipment, process automation, expanding data acquisition, and more.

Over our 30+ years in business, we have assembled one of the largest and most comprehensive testing facilities in our industry, allowing us to efficiently perform testing according to our exacting standards. This vertical integration methodology allows us to better control all factors, minimize lead times, and encourage experimentation through ease of access.

Our Equipment

10t Deadweight Test Machine

Humidity Test Machine

Coordinate Measuring Machine

600t Hydraulic Test Machine

Salt Spray Test Machine

Automated TC Span Test Machine

Learn More

We are continuously improving upon our quality assurance and manufacturing standards. By investing in equipment, technical expertise, procedural improvements, evaluating product feedback, and more, we constantly seek to push quality and performance standards in our industry to new limits.

If you’re interested in learning more about our facilities, how we can help with your testing & calibration needs, and the possibilities of load cell technology in weighing and force measurement, please contact us!